Well I've been wide open throttle here for a few months but feel like I'm spinning my wheels. I had to do another equity infusion (read: I had to stick more personal money into the business) to get things back on track with monthly payments and such. It took a bit more money and effort that I thought it would to get the new-to-me turning center up and running. It always does! I'll try to remember to link that thread here for posterity.

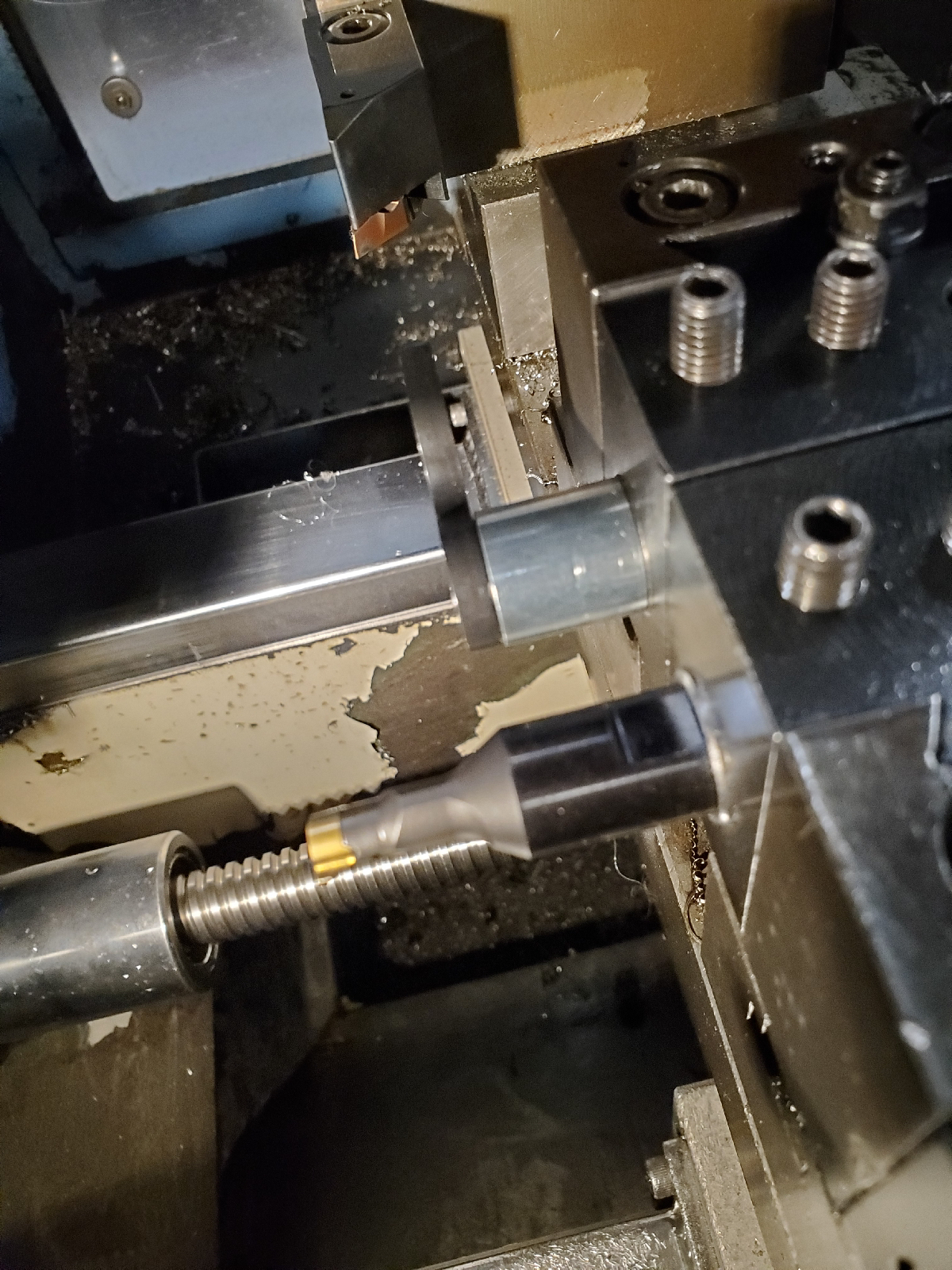

Made my first several batches of my hardened steel t-washers so technically the thing has already paid for itself. Waiting on honing of some collets so I can start doing my DOM tubing cutoff. That is gonna be a huge time saver!

The CCA Racing Products torque plate and other fixture sales have been picking up - lots of word-of-mouth referrals. I've been trying to streamline the ordering and payment/shipping process to minimize the amount of time I'm not making product. It has been very hard to keep up on production of the other stuff - hand tools and white label products - and I've been trying to get my production fixtures built for the hand tools.

Trying to get photos taken for the new website, but I'm gonna need a bigger photo booth! I have a local customer that has offered up theirs, but usually I have to ship these things the same day I make them so not a lot of time to run across town for a few pictures.

I'm also partnering with a US company to start supplying custom-labeled, US-made dial indicators with my hand tools. This is a big step up but I can still beat the crap out of most industry pricing, and I'll be the only one selling a 100% made-in-USA product. The engine building and race car world still cares about that sort of thing. Big thanks to Frank Mari for giving me a pointer to that company while he was on vacation.

These have to be the easiest-to-read dials I've ever seen.

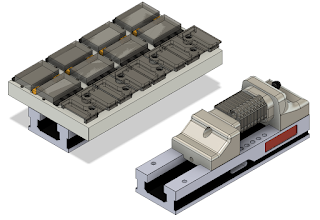

Starting on the production fixturing for that tool:

I'm building it so that I will just pull the vise jaws off my 20" Orange vise bodies and throw the pallet and "faux 4th" setup on there. I am building a -90/0/90 indexing system so I can do three operations on eight parts at once without moving anything fixture to fixture or vise to vise.

Speaking of Maritool... their new coolant skimmer is awesome. Less than $500 and so far the best one I've tried. That is about the same price as the Abanaki / Next Gen separatory tank type and the adjustability on this one is much easier than setting a float level! Plus it has a time delay setting so I can hit the button when I turn off the machine and it will wait six hours for the coolant to settle, then run for an hour.

Yeah, yeah. I guy who spent as much time as I have working with spent metalworking fluids should have gotten squared away with tramp oil removal a long time ago. Just goes to show how awesome modern quality coolants are.

As of this week I think I've had the Okuma on the floor for a year. Hard to believe, time really does start moving faster as you age.

Alright, I actually have a part that runs about 45 minute cycle time for OP1/OP2 combined so I was able to type this up and now I'd better get back to some shop maintenance stuff and building projects, and I also need to continue programming a few things. It never ends!

ETA: I meant to say that I did try those floating oil absorbing pillows from McMaster just to try a cheap stop-gap while I'm trying to not hemorrhage money, and it did not work AT ALL.

Thanks for sharing and look forward to seeing how things are doing in the future.

Thanks for sharing and look forward to seeing how things are doing in the future.