JP Machining

Stainless

- Joined

- Jul 15, 2006

- Location

- Wisconsin

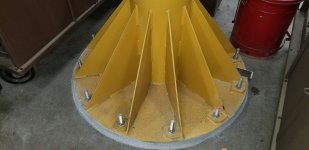

Well, crossed off one job I wasn't looking forward to this weekend. No one seems to tell you how much fun cleaning a water table out is when you're building it... went pretty well with an air hammer and getting underneath it. Definitely not waiting 4 years to do it again.

Scrap yard doesn't want the stuff as mix of steel and stainless so I guess it's off to the dump before too long.

Also removed the shelf from side of the table for the rotary as tired of reaching over it and have other ideas for rotary supports. Need to add a cable activated e-stop to the back of gantry so one doesn't get squished into rotary.

Scrap yard doesn't want the stuff as mix of steel and stainless so I guess it's off to the dump before too long.

Also removed the shelf from side of the table for the rotary as tired of reaching over it and have other ideas for rotary supports. Need to add a cable activated e-stop to the back of gantry so one doesn't get squished into rotary.

) Can't put one in the current setup with the infloor heat.........

) Can't put one in the current setup with the infloor heat.........