Ox

Diamond

- Joined

- Aug 27, 2002

- Location

- West Unity, Ohio

We have laws agginst distributing that stuff down here....

--------------------

Think Snow Eh!

Ox

--------------------

Think Snow Eh!

Ox

Not entirely sure that your reference to "power loss contactor" is what you think it is. They're not any more complicated or expensive than your standard contractor, really, but it's much safer. Momentary button energizes the coil, and a "loop" if you will, maintains coil energy after momentary button is released. If there is anything more than a power flicker it'll de-energize the coil and not turn back on until you press the button again. It really is that simple. Not any more expensive, it's a contractor with 1-4 additional "low amp" contactors on it, if that makes sense. When i built mine, they went any more expensive on fleabay than a contractor with no other contacts on it.

I'm aware it's just another contactor. But now I'm buying 2 instead of one then I'm adding another switch and wiring. And I always use contactors with 240v coil so I don't need a transformer. A lot of guys use what they have lying around so then end up using a 110v coil or 24v coil that needs a step down transformer or a neutral. Then if they are using the ground wire as a neutral they don't have a ground. Your ground should not carry working current. All at this power loss safety is built into your machine already isn't it.... So why the redundancy? If you loose power in a shop with 3 phase when the power comes back on it just comes back on doesn't it. All my machines utilize this technique with their built in contactor hooked to their individual start stop buttons. Just seams like bells and whistles to me. But to each their own. If someone wants to use it. I won't talk em out of it just tell em why I don't. If your machine doesn't already have this built into it and you start you RFC and your machine is on your in the same boat as a power loss without the safety built into the RFC.

http://www.metalworking.com/dropbox/_1998_retired_files/FRW-n.txt

http://www.metalworking.com/dropbox/_1998_retired_files/FRW-1.jpg

http://www.metalworking.com/dropbox/_1998_retired_files/FRW-2.jpg

http://www.metalworking.com/dropbox/_1998_retired_files/FRW-3.jpg

http://www.metalworking.com/dropbox/_1998_retired_files/FRW-4.jpg

http://www.metalworking.com/dropbox/_1998_retired_files/FRW-5.jpg

http://www.metalworking.com/dropbox/_1998_retired_files/FRW-6.jpg

I made a 10hp about 10 years ago and used the Fitch design. I don't think it is needed to put in a potential relay. Just look through these posts and see if you can find a post that contains the circuit for the potential relay.Are the old Fitch Williams designs available anywhere? The metalworking.com website is dead. I built my RPC using one of Fitch's designs 15 years ago and now I would like to modify it and add a Steveco potential relay.

-Dave

If a 3 phase system is wired properly thru a pushbutton stop/start contactor, the motor does not come back on after power loss. The fourth contact in the three phase contactor is wired in parallel to the start switch and holds in the contactor when you release the pushbutton.I'm aware it's just another contactor. But now I'm buying 2 instead of one then I'm adding another switch and wiring. And I always use contactors with 240v coil so I don't need a transformer. A lot of guys use what they have lying around so then end up using a 110v coil or 24v coil that needs a step down transformer or a neutral. Then if they are using the ground wire as a neutral they don't have a ground. Your ground should not carry working current. All at this power loss safety is built into your machine already isn't it.... So why the redundancy? If you loose power in a shop with 3 phase when the power comes back on it just comes back on doesn't it. All my machines utilize this technique with their built in contactor hooked to their individual start stop buttons. Just seams like bells and whistles to me. But to each their own. If someone wants to use it. I won't talk em out of it just tell em why I don't. If your machine doesn't already have this built into it and you start you RFC and your machine is on your in the same boat as a power loss without the safety built into the RFC.

Ok guys;

Here is my contribution to the cause. I'll just

move it up from a previous posting.

First is a picture of the finished RPC.

Motor and base actually came from an abandend

Commercial Air Conditioning unit, the motor

was new, so I took it. Recyclers only charged

me $20.00 bucks for it. For $5.00 more they let

me take all the caps and relays I could carry.

The case was a Junction box the recyclers sold

me for another $5.00. With a few odds and ends

the total cost was under $60 dollars.

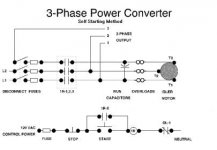

These are the schematics that I used. They're

based upon an original set of schematics of a

friend of mine, with my modifications.

ie: letting the L3 Voltage rise, determine when

to cut-out the start capacitor.

Jamie

Notice

This website or its third-party tools process personal data (e.g. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.