Lots of progress on the lathe lately, but most of the projects are unfinished so there's not much to report. But I did get the apron mounted, and I measured the total drop WRT the lead screw.

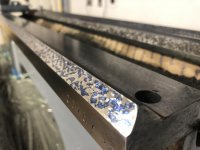

When I scraped the slides on the saddle, I had noticed that the apron mounting surface was about .005" concave. That's too much to ignore, or as soon as I tighten the apron mounting screws the front slide will distort convex. So I milled this surface down and scraped it flat. I didn't aim for perfect coverage because I really didn't want to remove too much material, or else I would have to adjust the gearing. The mating surface on the apron was in better shape than the saddle, but it needed a few cycles too.

After scraping I test-fit with the gears installed, it felt fine and there's still a little backlash. No adjustment needed.

Next I cut new bearings for the drive rod and got it installed. I measured the distance from the apron mounting surface with an indicator on a magnet base.

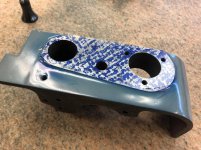

For the apron, I pressed an expanding mandrel into the worm carrier for the drive rod. I set the apron upside down on a surface plate, and used the same indicator setup to measure the height to the mandrel. The difference, plus the radius of the rod/mandrel gave me the total drop of the apron: .030".

I've already decided against building up the saddle slides with turcite, etc. My plan at the moment is to repin the gear-box and leadscrew support, I'll make some offset pins and enlarge the screw holes.

But while I was scraping the apron mounting surface I was thinking about adjusting the gearing, and I don't think it would be too hard. And I started thinking that instead of repinning the gear box, I could raise the apron instead by removing that .030" from the saddle and adjusting the gearing. The idler gear is a DP28, so I could cut a new gear with one less tooth for a diameter reduction of .035". I'd have to move the gear too. I think it's doable, maybe a little harder than repinning but the result might be cleaner. I'm considering it.