charlieman22

Aluminum

- Joined

- May 4, 2021

Gotten some further input.

Gaining a better understanding.

Looks like I have three options.

1. Set up a 208 single phase outlet - plug my current set up in - make chips.

Downside: my RPC is probably undersized, and defiantly noisy.

2. Loose the RPC/ use the building 3 phase. Aquire an up converting 3-PH Wye transformer with 208/416 delta.

3. Similar to 2, use a down converting transformer in reverse. May be more complicated to wire - needing "corner grounding". Some 3-PH converters apparently don't do this well?

Question revised: Could use some help spec'ing solutions 2 or 3.

Trying to get good results/control costs - of course.

Existing converter is down type, run in reverse - with buck boost (which I think gives me an additional 16-32 volts on my existing system.)

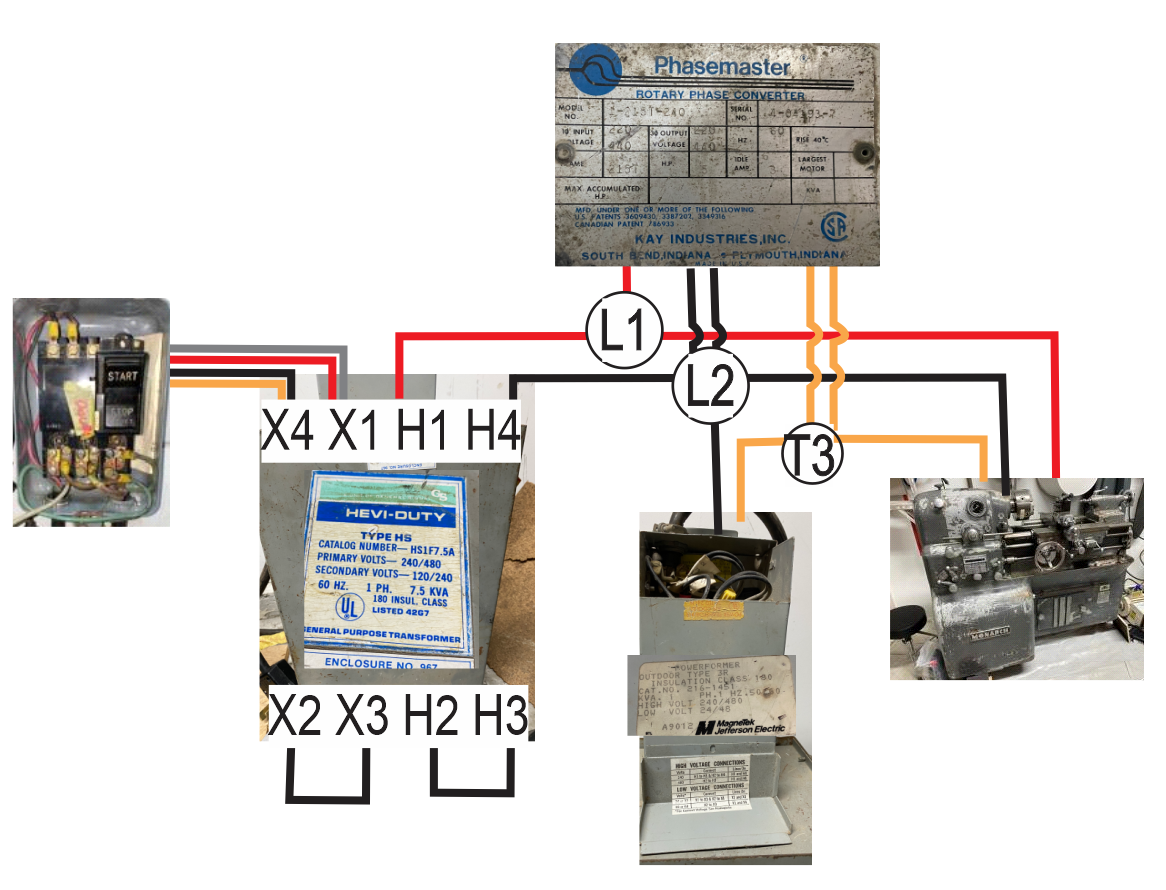

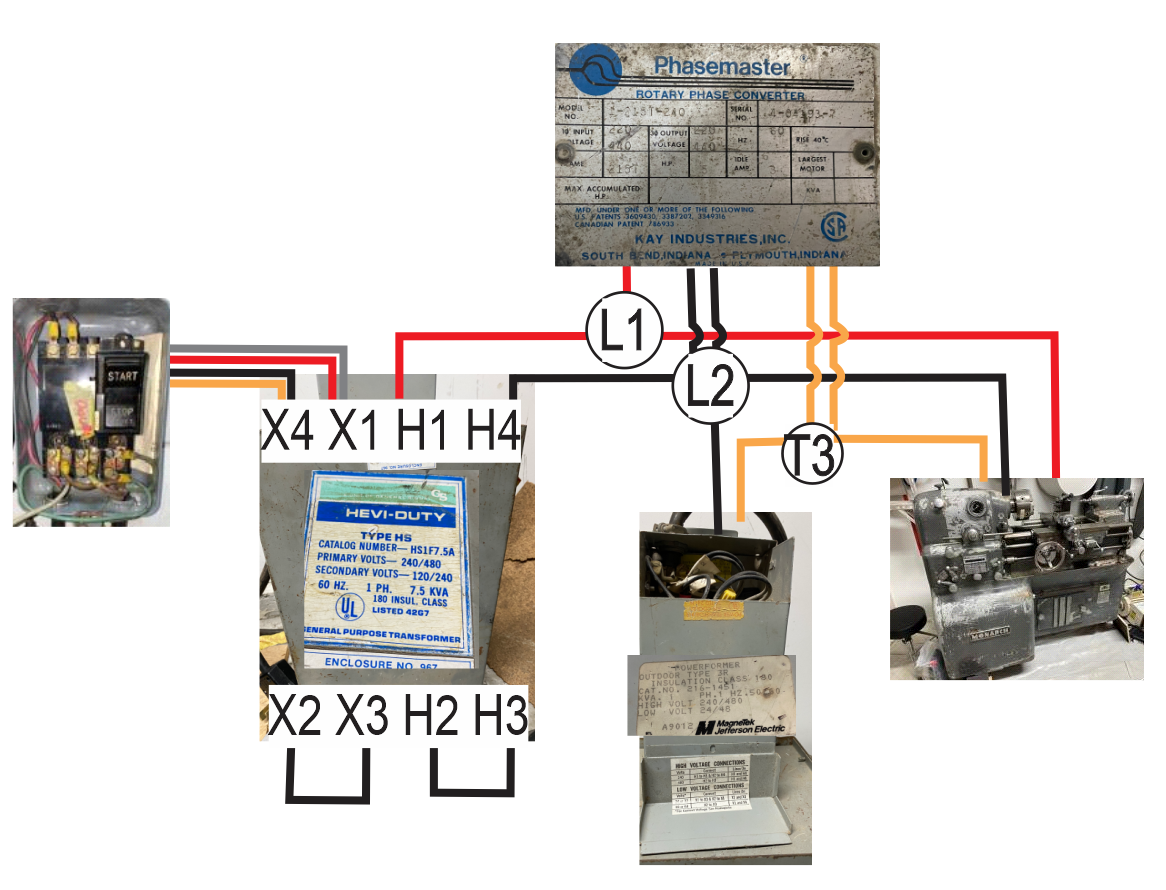

Better diagram of existing attached here.

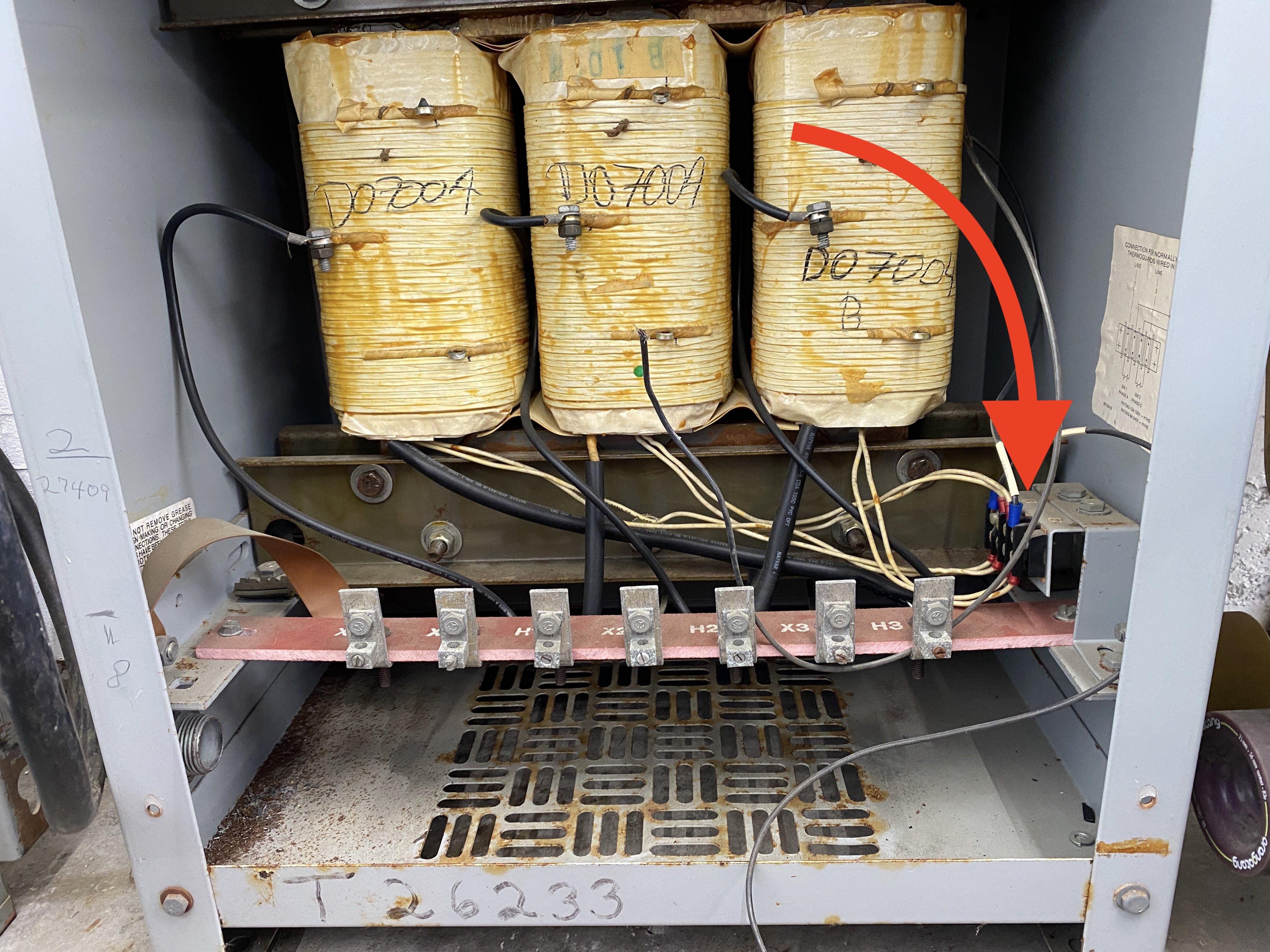

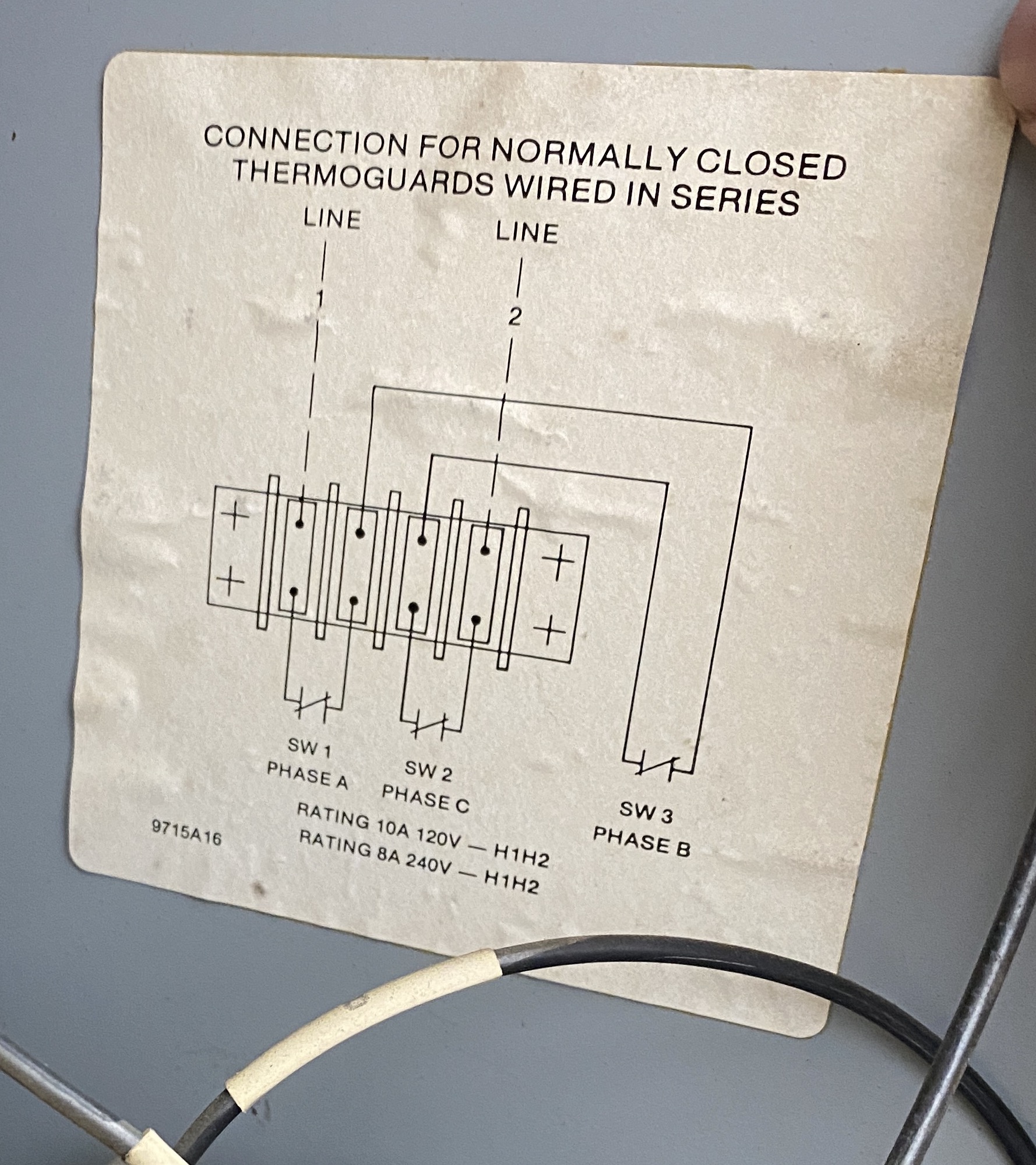

Also - notes page from inside the RPC I found - showing it is wired for 440, and how the Buck up converts to 460 - I believe.

Posting here so its clear and I have it for my reference in the future.

Gaining a better understanding.

Looks like I have three options.

1. Set up a 208 single phase outlet - plug my current set up in - make chips.

Downside: my RPC is probably undersized, and defiantly noisy.

2. Loose the RPC/ use the building 3 phase. Aquire an up converting 3-PH Wye transformer with 208/416 delta.

3. Similar to 2, use a down converting transformer in reverse. May be more complicated to wire - needing "corner grounding". Some 3-PH converters apparently don't do this well?

Question revised: Could use some help spec'ing solutions 2 or 3.

Trying to get good results/control costs - of course.

Existing converter is down type, run in reverse - with buck boost (which I think gives me an additional 16-32 volts on my existing system.)

Better diagram of existing attached here.

Also - notes page from inside the RPC I found - showing it is wired for 440, and how the Buck up converts to 460 - I believe.

Posting here so its clear and I have it for my reference in the future.