Thanks for the manual PDFs! Now I've got an easy question and a hard question. Regarding oil, does this look like a reasonable option?

AW Hydraulic Gear Oil Fluid ISO VG 68 SAE 20 Industrial Machinery Excavator 5gal

AW Hydraulic Gear Oil Fluid ISO VG 68 SAE 20 Industrial Machinery Excavator 5gal 614654010744 | eBay

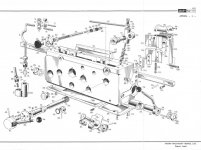

And now the hard question: Do any Okuma LS owners have a drawing or picture with rough dimensions of the micrometer carriage stops? Mine did not come with these and I'd like to replicate the original design as closely as I can. Alternatively, if someone has extras or an appetite to make one I'd buy!

AW Hydraulic Gear Oil Fluid ISO VG 68 SAE 20 Industrial Machinery Excavator 5gal

AW Hydraulic Gear Oil Fluid ISO VG 68 SAE 20 Industrial Machinery Excavator 5gal 614654010744 | eBay

And now the hard question: Do any Okuma LS owners have a drawing or picture with rough dimensions of the micrometer carriage stops? Mine did not come with these and I'd like to replicate the original design as closely as I can. Alternatively, if someone has extras or an appetite to make one I'd buy!

So now I got to make a new one but I don't know if it has to be out of cast iron. What would you say?

So now I got to make a new one but I don't know if it has to be out of cast iron. What would you say?