OK the guy who designed the oil tank mounting system was a sadist, three bolts in a space where you can barely get a hand in let alone a position that any yoga expert would consider madness, I understand now why only one bolt was actually fitted when I got the lathe!

The tank went in and out 5 times before I was able to bend the feet into a position that allowed the holes to line up to kick of with, again you cannot see if they are aligned and have to do the whole thing by feel with copious amounts of pain and no doubt a trip to the chiropractor too ....

Anyway once I got the alignment right and managed to get all three bolts in by hand as far as they would go the time to do them up threw yet another challenge, getting an Allen key in there is impossible, I ended up grinding the short end of a key close to the bend so I could get it to locate, then on the two bolts at the back of the mount you literally had about a quarter turn available to tighten them as you had no room to work, it took me almost 45 minutes to do up 3 bolts £$%&!!!!!!

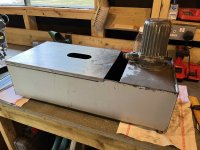

Hope it does not need to come out anytime soon but it's in now (better not leak!).

Hooked up the new tank vent pipe, using the spare port now not needed as the Variator has no oil feed return, connected up the head gear drain via the 12mm OD push fit pipe back to tank and started to plan the 10mm OD pipe route up to feed the head gear from the pump.

Painful but done, god bless Schaublin ...

View attachment 369002

View attachment 369003

View attachment 369004