Best Fit, the dog-n-pony show trick where you probe in the machine and update the CAD model?

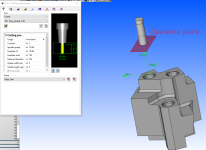

Or as I like to think of it - backwards dynamic work offsets. Yes, NX can do it:

It is a nice trick, but the real challenges are on the machine and probe side, not so much the CAM side. For simple parts in a centering vise, you just need 2 planes, feed that data back into the CAD side, and use that to orient the part. The demo above is far more complicated as the part has no orthogonal surfaces, so the Blum software is feeding point clouds back to NX, which is low-key using some of the reverse engineering tools (Best Fit surface) to match that scan data to the part model and re-orient it. In NX, all of what you see in that demo are existing tools; the work is integrating them all into one seamless package...

Which is why NX kinda blows everything out of the water on high-complexity applications. The CAD and CAM side can work together in ways that other systems simply can't. Now, how much of that messy integration work the fine folks at Siemens do and offer as turnkey solutions is another matter, but NX Open gives you the ability to solve basically any complex manufacturing issue.

Yes, NX has strategies for circle segment cutters.