OK, some have pointed out key *business level* issues - training, safety, risk.

Yes, people can learn new CAM systems (and to some extent should), but WHAT IS THE RETURN????

So your new staffer wants to use WeirdCAM, so buy them WeirdCAM. But nobody else in the shop knows how to use it, and new staffer took months to really learn it - which you paid for (or they paid for - somebody paid.) How long to earn that back? (empower *already knowing* several CAM systems will be an advantage going forward, but what did it cost empower to do that?)

What if instead you or your staff developed elite skills using libraries, tables, macros, fixture modeling, post refinement, etc., for the tool already in use? I know for solidcam (which is NOT mastercam) these things can have a big return.

Would your resource (time, money, attention) be better spent adding something like vericut or ncsimula (sp?) to the workflow?

One DOES hear of people buying something like an Integrex or a Multus and then buying CAM specific to that machine.

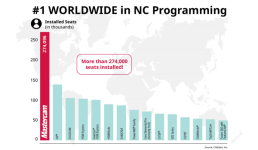

That chart claims to be *installed* seats - one question is what are their sources??? - could easily be some large users ignore them. There are also likely environments (esp aerospace) where it's part of the "environment" and they aren't allowed, or are very loathe, to change it.

[Decades ago in grad school fellow student told me that for work on a aircraft system, the compiler used to write the control software was frozen, along with other tools. Bug in the compiler? Tough - work around it. By the way there are very real security as well as stability reasons to do this. But point here - how many environments are there where "change the CAM system" makes as much sense as "change the break room fridge from 120volt 1ph to 208volt 3ph".]

That doesn't mean mastercam is wonderful or awful, any more than haas ngc is best or worst - it just means that context matters a very great deal.