+/- tolerance is allowed. When I worked in a machine shop that made scales for logging trucks we had a +/- of about 0.04 inches. And if things workout for me, with a shop to work in I could probably get things within +/- 0.01 inch. And with what I'm building, it is a prototype. And if it works, then this build along with 2 or 3 others I have done will probably wind up in a museum in Saxony, Germany. Johann Bessler (1680 - 1743) lived in the Republic of Saxony which today is Saxony, Germany.I thought this sounded a bit familiar. It's On the Waterfront with Marlon Branflake. "You don't understand! I could've had class. I could've been a contender. I could've been somebody..."

I've looked at your spreadsheet snippets, which are meaningless without column headings, but I do notice that you are quoting lengths to an accuracy of 10 microinches, or one micrometre. Tell me Clim, how are you going to achieve that with hand-worked wood?

George

As for the math, I'll be able to say that scientists made this a toxic subject for one simple reason, they say gravity has no energy. And since gravity has no energy, the

momentum/force that gravity generates in a falling mass/body cannot be conserved.

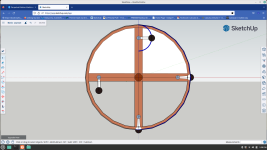

I've simplified the design in this drawing. When the weight passing top center is rotated 180º, the weight 90º after top center is the weight that is falling. If the weight is overbalanced by .25m then the top weight is being lifted .5m. This means that the weight 90º after top center needs to drop from .25m above the level of the axle to .25m below the level of the axle. And to rotate the weight passing top center will use only about 62% of the torque generated. I am building something using what Bessler called a "Peacock's Tail" so it will be somewhat authentic. The question is can the other 2 weights that are falling rotate the wheel? And at times all 4 overbalanced weights will generate torque/momentum. That's why I like this design.

With the spreadsheet, I'm not sure how many people use them. And if people don't use trigonometry to calculate torque then they wouldn't be familiar with the math.

I used 0º cosine to 90º Cosine and averaged it for the various frames of reference. Basically when is torque being generated and when does work being performed

decrease the amount of torque being generated. How I was able to calculate the net torque for what I'm building at about 9.3 in.lbs. of torque on average.

The radius of the wheel I'm building will be about 20" or 0.5m. This makes the "drop" of a weight about 1m. The average is 0.5m. Then if .5/9.81 = 0.05m/s.

Of course resistance would reduce that but then how much won't be known without it being built. Also the amount of overbalance might be able to be doubled.

Still, .04m/s with a 3.142 meter circumference translates to a little less than 1 rpm. I'm okay with that because this is impossible. And yet if it rotates more quickly than what math suggests then it will give a better understanding of how math applies to something like this.

Attachments

Last edited: