You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Efficiency Suggestions

- Thread starter Ronno6

- Start date

- Replies 62

- Views 0

That's worth a shot!A keyless drill chuck should be a little quicker than keyed.

lodge&davis

Plastic

- Joined

- May 10, 2013

- Location

- Ilinois

A jacobs chuck for each tool that you put in the tail stock would save a lot of time.A keyless drill chuck should be a little quicker than keyed.

L Vanice

Diamond

- Joined

- Feb 8, 2006

- Location

- Fort Wayne, IN

Forty years ago, I used my 1944 Hardinge ESM59 lathe to make a few thousand parts for a local manufacturer. This is the model with split bed that came before the 1946 DV59. The lathe came with a turret, lever cross slide, slide rest and conventional tailstock, but no tooling. There were several different parts to make on the lathe and I got orders for only one or two hundred at a time for each part. I did make double or triple orders to save on changing setups once it looked like a steady demand. I had to buy turret tooling for the job (before eBay), but I priced the parts to allow for tooling and leave me money for food and expenses, so I did OK. I found it was fun to plan how to make each part, set the lathe up and run the parts. More fun than work. Most parts took me only a few seconds each versus what the company owner used to spend doing them on his 9" South Bend when he first started out making product one at a time. He was happy with my work and prices. I only needed one special tool done at a grind shop, a curved shape blade for the Hardinge skiving tool. The product is shown below. It was too expensive for me to buy one for myself (I preferred to buy more machine tools). Production ended after a few years when some laws changed.

I had a lever collet closer, but no bar feeder. I used relatively short steel bars, depending on the diameter. The 5/16 bars and up were 3 feet long, but the 1 inch were 6 feet. It is good to have a support bushing in the left end of the collet draw bar to prevent whipping.

I have a turret buried out in my garage that may well be for a Logan. I think it has no name on it and I have not looked at it in thirty years, so I do not recall what swing it may fit. It would be cheap, though shipping might cost a bit.

Having a lever cross slide is a great time saver for some jobs, but drilling and reaming with a turret will be a great help compared to changing bits in a chuck. Most turret tooling has provision for working accurately even if the tool holes in the turret do not exactly line up with the headstock. Drill bits are best held in a Brookfield or similar clamp and V-block holder, not a Jacobs chuck.

Larry

I had a lever collet closer, but no bar feeder. I used relatively short steel bars, depending on the diameter. The 5/16 bars and up were 3 feet long, but the 1 inch were 6 feet. It is good to have a support bushing in the left end of the collet draw bar to prevent whipping.

I have a turret buried out in my garage that may well be for a Logan. I think it has no name on it and I have not looked at it in thirty years, so I do not recall what swing it may fit. It would be cheap, though shipping might cost a bit.

Having a lever cross slide is a great time saver for some jobs, but drilling and reaming with a turret will be a great help compared to changing bits in a chuck. Most turret tooling has provision for working accurately even if the tool holes in the turret do not exactly line up with the headstock. Drill bits are best held in a Brookfield or similar clamp and V-block holder, not a Jacobs chuck.

Larry

Last edited:

Yessir. i have considered that.A jacobs chuck for each tool that you put in the tail stock would save a lot of time.

Just to clarify, I see the phrase "turret tailstock" being an item under consideration for the work. It MIGHT work, but I would highly recommend a bed-mounted turret rather than something in the tailstock. In my experience, those setups are always disappointing. I agree that setups on a Hardinge or any other turret-equipped machine can be a little finicky if you are trying to turn diameters to dimensions using tools in the turret, but for on-center operations like drill/cbore/ream, etc. they are way more efficient.

Yessir. A bed mounted turret is what I am considering.

The Logan part # is LA-70 or some variation of that.

I have seen 1 lever operated unit, but most have a rack and pinion rotating handle for actuation.

I do understand that the Logan units auto index the turret when the slide is cycled in/out.

i would indeed need to turn the OD to dimension unless I did that on another machine and bar fed on size stock. That might get tricky obtaining a 5C collet of the correct, on size dimension.

The Logan part # is LA-70 or some variation of that.

I have seen 1 lever operated unit, but most have a rack and pinion rotating handle for actuation.

I do understand that the Logan units auto index the turret when the slide is cycled in/out.

i would indeed need to turn the OD to dimension unless I did that on another machine and bar fed on size stock. That might get tricky obtaining a 5C collet of the correct, on size dimension.

L Vanice

Diamond

- Joined

- Feb 8, 2006

- Location

- Fort Wayne, IN

The possibly Logan turret I have is what some call a bed turret.Yessir. A bed mounted turret is what I am considering.

The Logan part # is LA-70 or some variation of that.

I have seen 1 lever operated unit, but most have a rack and pinion rotating handle for actuation.

I do understand that the Logan units auto index the turret when the slide is cycled in/out.

i would indeed need to turn the OD to dimension unless I did that on another machine and bar fed on size stock. That might get tricky obtaining a 5C collet of the correct, on size dimension.

A roller box tool, balance turning tool or a knee tool mounted in the turret will turn the bar OD to a smaller size. The box tool usually does a better finish.

Hardinge makes 5C collets in any inch size by .001 increments. I have a .300" 5C collet I got for a particular second operation job. But it is best to get standard size bar stock, which will fit common size collets, whether fractional inch of metric.

I looked up the Logan turrets on Tony's site and see they have 5/8" tool bores. That is the same size as most Hardinge turrets and Hardinge, Brown & Sharpe, Somma, Boyar-Shultz and others made millions of tools to fit. Lots of them on eBay, so it is easy to get the tooling.

Larry

Last edited:

pan60

Cast Iron

- Joined

- Jan 3, 2013

- Location

- Arkansas USA

but at the end of the day a bed mounted turret is not going to do the same job the hardinge will. at least not as i can see?

a proper turret will handle that end of the job but as i see he stoo wont have a double cross slide and yes he can get by with out it but we are talking efficients and cost

nest i dont see a propper collet system. i have no clue what the logans can handle but a chuck would work and agin not so efficient?

i many many years ago spent far to much money trying to make a south bend into a production machine thinking i was saving some money. i spent more monet on a proner turret then the last hardigme i picked up cost me.

by the he he rounds up all the part to get his logan close to a hardinge he still will fall short? at least how i see it. and most likey spend as much money.

but i could be very wrong.

my rcomendtaion was to shop a aound a find a hardinge and that was based on the above thoughts.

i also aruge him to seak advice here not just on the hardinge but also in how best to run the parts.

thanks

a proper turret will handle that end of the job but as i see he stoo wont have a double cross slide and yes he can get by with out it but we are talking efficients and cost

nest i dont see a propper collet system. i have no clue what the logans can handle but a chuck would work and agin not so efficient?

i many many years ago spent far to much money trying to make a south bend into a production machine thinking i was saving some money. i spent more monet on a proner turret then the last hardigme i picked up cost me.

by the he he rounds up all the part to get his logan close to a hardinge he still will fall short? at least how i see it. and most likey spend as much money.

but i could be very wrong.

my rcomendtaion was to shop a aound a find a hardinge and that was based on the above thoughts.

i also aruge him to seak advice here not just on the hardinge but also in how best to run the parts.

thanks

jim rozen

Diamond

- Joined

- Feb 26, 2004

- Location

- peekskill, NY

"You could have a WEDM shop cut you form tools with chamfers, radii whatever on them. Might make set ups a little quicker."

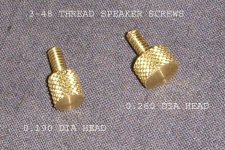

Yep this works. One example, thumbscrews done with a form tool and knurling Hardinge ESM59, the smaller thumbscrews were done on a smaller lathe with a schaublin 70 turret.

Yep this works. One example, thumbscrews done with a form tool and knurling Hardinge ESM59, the smaller thumbscrews were done on a smaller lathe with a schaublin 70 turret.

Attachments

By far the most cost conscious manner foe me to produce these parts is the way I have been doing it. I doubt that the cost of a new machine would ever be recaptured

I'm just a poor, old retired hobbyist............on or off the table depends on your definition of "cheap"Turret lathe?

Cheap little barfed cnc lathe would kill these things.

Is cnc off the table? If so, why?

L Vanice

Diamond

- Joined

- Feb 8, 2006

- Location

- Fort Wayne, IN

I saved a few of the potentially useful for other things knurled screws from that 80's project. Made on the Hardinge ESM59 at the rate of several per minute.

One or two turret roller box tools, turret Geometric die head, turret knurling tool, gang of front cross slide tools to face and chamfer and rear cross slide tool to cut off.

Larry

One or two turret roller box tools, turret Geometric die head, turret knurling tool, gang of front cross slide tools to face and chamfer and rear cross slide tool to cut off.

Larry

memphisjed

Stainless

- Joined

- Jan 21, 2019

- Location

- Memphis

Is there a reason turret is better than a chucker arrangement on these parts? No wild set up, a small nc lathe that would be open for other lathe stuff 99.99 percent of the time.

Or just use lathe existing and set it up as a chucker gang across the slide?

Or just use lathe existing and set it up as a chucker gang across the slide?

By far the most cost conscious manner foe me to produce these parts is the way I have been doing it. I doubt that the cost of a new machine would ever be recaptured

I'm just a poor, old retired hobbyist............on or off the table depends on your definition of "cheap"

Small older cnc lathe under $2000 isn't hard to find.

With cnc your quality would improve as well. Parts would be shiny and burr free.

Overland

Hot Rolled

- Joined

- Nov 19, 2017

- Location

- Greenville, SC

I had a little project yesterday that was 6 holes for tapping 1/2"-13, 1.42" deep into some pieces of bar.

I spent a few minutes to set up a morse taper holder & Jacobs chuck in my Aloris, and used the DRO to give me depth. Ended up being well worth the set up.

So maybe an Aloris toolpost, some MT holders for the various tools and make notes of the DRO "X" & "Y" dimensions might be a simple way to speed things up a bit.

Much easier to use the carriage auto feed, than the manual tailstock.

Bob

I spent a few minutes to set up a morse taper holder & Jacobs chuck in my Aloris, and used the DRO to give me depth. Ended up being well worth the set up.

So maybe an Aloris toolpost, some MT holders for the various tools and make notes of the DRO "X" & "Y" dimensions might be a simple way to speed things up a bit.

Much easier to use the carriage auto feed, than the manual tailstock.

Bob

Scottl

Diamond

- Joined

- Nov 3, 2013

- Location

- Eastern Massachusetts, USA

If you can find one of the old lever operated speed lathes with turret, fine. If not there are "gadgets" you can build to make your Logan perform similar functions. Start with a bolt on lever operated "slide" with rear mounted cutoff tool and maybe an upside down turning tool with 2 normally mounted tools on the front side. It would need at least 2 levers. Either buy/make a turret or make a quick change tool holder for your tail stock. Unplug one tool and plug in the next with cutting depths preset. Make one of the tools a swing away depth stop (or use a fixed stop and removable spacer) so you can pull the stock forward after cutoff and eliminate the facing operation on the washer.

This type of stuff was common in the days of plain turning lathes and a lot of the old books are available digitized online for free.

This type of stuff was common in the days of plain turning lathes and a lot of the old books are available digitized online for free.

I think you should get a quote from a properly equipped shop for a quantity that will last a reasonable length of time. Maybe a thousand of each. For the right guy with the right tools it looks simple and fast - and that should make the cost pretty good compared to buying a new machine.Another member strongly urged me to post here for suggestions.

I make several parts for obsolete pellet rifles.

Either to make available parts that are not obtainable anywhere else, or to

offer more affordable alternatives to those who supply obsolete parts at outrageous prices.

These two parts restore function to some obsolete Daisy pellet rifles.

View attachment 383950View attachment 383951

Both are turned from 6061 aluminum on a manual Logan 820 tool room lathe, and I make about 300 of each per year.

I have been thinking of ways to make the process simpler, more efficient and with more repeatable accuracy.

It has been suggested that I find a good second operation turret lathe, such as a Hardinge DSM-59.

I live in south Mississippi; not exactly the machining mecca of the universe...

I have been looking at adding a turret tailstock, moreso for the washer than the button.

the washer requires up to 4 drilling/boring/reaming operations, along with a facing, an O.D. reduction and 1 cut to machine the flange and a parting off.

The button requires a facing, O.D. reduction, concave shoulder cut that also requires a Z-axis move, the turning of the smaller diameter and parting off.

Would machining of these components benefit from a lever production cross slide?

I am not a professional machinist, but do OK with what I have to work with..

Any help would be appreciated.

Thanks.