I almost feel bad that we caught Darrin/VW/AS so quick this time. Kind of a let down, like guessing the end of a book too soon.

The AS9100D personality was so much better done. Months spent posting the wonders of ISO and building up trust to sell some stolen Haas's, and he even posted genuinely helpful info a few times (amid the blacked out screenshots, of course).

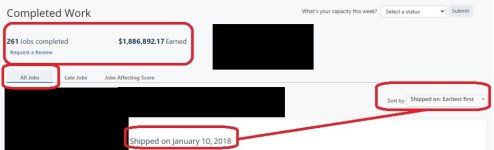

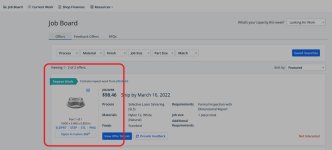

And this time all we get is some Xometry bragging.... We should blame Biden, high gas prices, inflation, and lazy scammers.

The AS9100D personality was so much better done. Months spent posting the wonders of ISO and building up trust to sell some stolen Haas's, and he even posted genuinely helpful info a few times (amid the blacked out screenshots, of course).

And this time all we get is some Xometry bragging.... We should blame Biden, high gas prices, inflation, and lazy scammers.