Stirling

Hot Rolled

- Joined

- Dec 11, 2013

- Location

- Alberta canada

im looking at making/stocking a replcement part products, they are cast housing products, i can make from billet if needed, but im wondering the feasability vs small batched of castings. nothing needs to be crazy accurate, just a casting that i can machine a few features too.

is 30-50 pc castings feasable?

4 aluminum products

2 steel products

alm

15" dia x 2.5 tall casting material is approx 30% of would be billet volume

15" dia x3.5 tall casting material is approx 2% of would be billet volume

5" dia x 2.5" tall material is approx 30% of would be billet volume

5" dia x 2.5" tall material is approx 30% of would be billet volume.

steel

6" dia x 5" tall material is approx 30% of would be billet volume

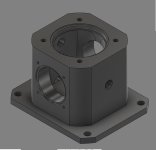

10dia x 5 3/4 tall material is approx 15% of would be billet volume, this one is a bit mre complicated casting as it hase a void inside, see photo

the other castings are do in mybackyard simple, but im not gonna do that!

im sure they are simple for someone that deals with it everyday, but i never request castings so ill lean on your learned experiences for help (thanks!)

theres many ways to skin a cat, im always from billet but i think this job will b ebetter off cast.

Any considerations im not thinking about? should knows? money saving tips?

i can send cad with draft angles, i could 3d print oversized(for shrinkage) parts and they could pound sand around/into them. i dunno, im casting clueless!

and lastly, any recomended casting houses? preferably in canada?

is 30-50 pc castings feasable?

4 aluminum products

2 steel products

alm

15" dia x 2.5 tall casting material is approx 30% of would be billet volume

15" dia x3.5 tall casting material is approx 2% of would be billet volume

5" dia x 2.5" tall material is approx 30% of would be billet volume

5" dia x 2.5" tall material is approx 30% of would be billet volume.

steel

6" dia x 5" tall material is approx 30% of would be billet volume

10dia x 5 3/4 tall material is approx 15% of would be billet volume, this one is a bit mre complicated casting as it hase a void inside, see photo

the other castings are do in mybackyard simple, but im not gonna do that!

im sure they are simple for someone that deals with it everyday, but i never request castings so ill lean on your learned experiences for help (thanks!)

theres many ways to skin a cat, im always from billet but i think this job will b ebetter off cast.

Any considerations im not thinking about? should knows? money saving tips?

i can send cad with draft angles, i could 3d print oversized(for shrinkage) parts and they could pound sand around/into them. i dunno, im casting clueless!

and lastly, any recomended casting houses? preferably in canada?