localbiker

Plastic

- Joined

- Nov 18, 2022

I am an apprentice machinist+Turner. Our shop currently only uses long-handed programming and as i see myself wanting to learn cam i have been self-teaching myself using learners addition.

I have been running into these issues on a number of moch parts.

So far i have been working my way through the university tutorials , MLC cad tutorials , and glanced over titans of cnc lessons.

Has anyone any other recommendations for learning, Its challenging being faced with constant errors/crashes,collisons and not having a the sense on how to trouble shoot the issues.

Currently experiencing

- Excessive Feed toolpath times, -

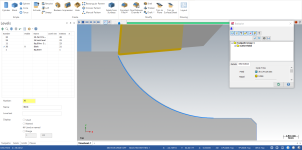

-Finish tool path cuts into the material/Body of component

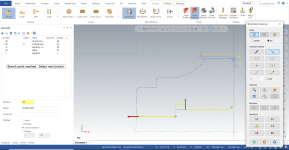

-Chain selection on Internal Bore. , It either follows the undercut or includes the full shoulder when selected,

I have been running into these issues on a number of moch parts.

So far i have been working my way through the university tutorials , MLC cad tutorials , and glanced over titans of cnc lessons.

Has anyone any other recommendations for learning, Its challenging being faced with constant errors/crashes,collisons and not having a the sense on how to trouble shoot the issues.

Currently experiencing

- Excessive Feed toolpath times, -

-Finish tool path cuts into the material/Body of component

-Chain selection on Internal Bore. , It either follows the undercut or includes the full shoulder when selected,