Hi Guys,

Not sure if I'm doing something silly or if it's some problem in Fusion or in my post.

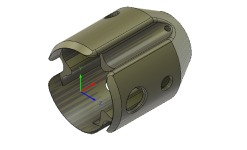

So I'm trying to machine a part on my HURCO VM10i with a 4th axis. Ignoring all the other features I've tried to do a simple spot drilling operation. I do the spot drill at the model WCS then create a pattern to repeat the same operation at two other locations 120 degrees around the part.

In the output G code the first hole looks good:

N90 G98 G81 X65. Y0. Z41.57 R51.472 F413.8

Much what I'd expect. The second and third holes are at different Y and Z locations though:

140 G81 X65. Y0.92 Z43.164 R53.066 F413.8

I then tried scrapping the pattern function and doing three drilling ops using the "tool Orientation" function in the geometry tab selecting the hole as my Z reference and I get the same issue. I've spent hours on this now and have absolutely no idea why it is doing this. Does anyone have any suggestions?

For reference, in the WCS for the main setup I have Y and Z zero at the A axis centreline, X zero at the face of the part.

Not sure if I'm doing something silly or if it's some problem in Fusion or in my post.

So I'm trying to machine a part on my HURCO VM10i with a 4th axis. Ignoring all the other features I've tried to do a simple spot drilling operation. I do the spot drill at the model WCS then create a pattern to repeat the same operation at two other locations 120 degrees around the part.

In the output G code the first hole looks good:

N90 G98 G81 X65. Y0. Z41.57 R51.472 F413.8

Much what I'd expect. The second and third holes are at different Y and Z locations though:

140 G81 X65. Y0.92 Z43.164 R53.066 F413.8

I then tried scrapping the pattern function and doing three drilling ops using the "tool Orientation" function in the geometry tab selecting the hole as my Z reference and I get the same issue. I've spent hours on this now and have absolutely no idea why it is doing this. Does anyone have any suggestions?

For reference, in the WCS for the main setup I have Y and Z zero at the A axis centreline, X zero at the face of the part.