Hi everyone,

Dumb question, I know, but hear me out -

My business had a very profitable year and I decided to reinvest some of those winnings into a VF4SS+TRT210 to bring some production in-house. It is end of the year, so all the software distributors have their biggest sale of the year going. It would make sense to buy now (tomorrow), but I have 2 problems:

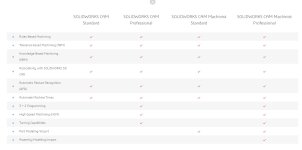

1) I haven't dedicated the necessary time to deep dive all CAM options, and I feel silly spending 5axis CAM money on a product that I haven't fully investigated. Currently eyeballing CAMWorks, TopSolid, and MasterCam, but not clear on differences. I have quotes though! We use Solidworks for design if that matters at all.

2) The mill wont be installed until early summer of next year due to some shop construction. We're not in a rush for the machine, and it feels silly to pay maintenance on software that I'm not even using.

So come summer next year I'll be ready for CAM, but the prices will all suck. I'm thinking maybe wait untill this time next year to buy. MY QUESTION (finally, I know right?): Will I be able to manually program simple parts on the machine console? I'm thinking this would be a great way for us to get acclimated to the machine before the 5axis fancy software is available. Please let me know if this is dumb and the machine is effectively a brick without proper CAM. All I know is Bridgeport EZ-TRAK, so I have a learning curve no matter what and most of the CAM capability will be wasted on me (for a few months at least).

Thanks!

Dumb question, I know, but hear me out -

My business had a very profitable year and I decided to reinvest some of those winnings into a VF4SS+TRT210 to bring some production in-house. It is end of the year, so all the software distributors have their biggest sale of the year going. It would make sense to buy now (tomorrow), but I have 2 problems:

1) I haven't dedicated the necessary time to deep dive all CAM options, and I feel silly spending 5axis CAM money on a product that I haven't fully investigated. Currently eyeballing CAMWorks, TopSolid, and MasterCam, but not clear on differences. I have quotes though! We use Solidworks for design if that matters at all.

2) The mill wont be installed until early summer of next year due to some shop construction. We're not in a rush for the machine, and it feels silly to pay maintenance on software that I'm not even using.

So come summer next year I'll be ready for CAM, but the prices will all suck. I'm thinking maybe wait untill this time next year to buy. MY QUESTION (finally, I know right?): Will I be able to manually program simple parts on the machine console? I'm thinking this would be a great way for us to get acclimated to the machine before the 5axis fancy software is available. Please let me know if this is dumb and the machine is effectively a brick without proper CAM. All I know is Bridgeport EZ-TRAK, so I have a learning curve no matter what and most of the CAM capability will be wasted on me (for a few months at least).

Thanks!