Corry

Plastic

- Joined

- Feb 21, 2011

- Location

- Fairfax, VA

I have never quoted out a part in my life, so be gentle  . I also am just my own private job shop, so the only RFQ's I've seen are my own

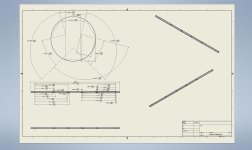

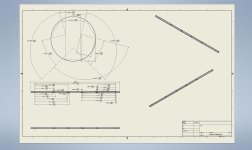

. I also am just my own private job shop, so the only RFQ's I've seen are my own  (small research project) I've probably got something really stupid in this drawing making it so I get no quotes, or no replies. In my RFQ I even specify I'm new at this, and if something looks stupid, talk to me and help me to understand. I get it that most shops are busy now (see the thread with the GBI), so most don't want to take the time to "educate me", but I did figure, for a sinker EDM, this would be an easy job. A bunch of conical divots (seats for conical set screws) and some small holes. I relaxed the tolerances, basically under advice from an EDM dealer, to say I don't need parts run on a CMM afterwards, and I'm asking for more than I need, so if there happens to be a reject in the bunch, I have extras. Any EDM made after about 1995 should be able to hold 0.0002", and the angle tolerances are good for a manual rotary (I think) or a fixture with angles cut in. I figured this would be a "gravy" job (easy, low time, pays well). Only complication would be fixturing, since it is rather long. (Yes, I'm also the idiotic mechanical engineer who designed this stupid thing...there's no way around having this noodle. There are parts with tight tolerances that fit over it to stiffen things up, but I need to assemble moving parts onto it, and this will be a bearing surface once hardened and nitrided). Part is from maraging 300. I have some ground, but not straightened stock. I also bought some new stock to have straightened then ground (since I think that's the order of operations?) I also don't mind a shop quoting the stock, grinding, and straightening, and said so in my RFQ.

(small research project) I've probably got something really stupid in this drawing making it so I get no quotes, or no replies. In my RFQ I even specify I'm new at this, and if something looks stupid, talk to me and help me to understand. I get it that most shops are busy now (see the thread with the GBI), so most don't want to take the time to "educate me", but I did figure, for a sinker EDM, this would be an easy job. A bunch of conical divots (seats for conical set screws) and some small holes. I relaxed the tolerances, basically under advice from an EDM dealer, to say I don't need parts run on a CMM afterwards, and I'm asking for more than I need, so if there happens to be a reject in the bunch, I have extras. Any EDM made after about 1995 should be able to hold 0.0002", and the angle tolerances are good for a manual rotary (I think) or a fixture with angles cut in. I figured this would be a "gravy" job (easy, low time, pays well). Only complication would be fixturing, since it is rather long. (Yes, I'm also the idiotic mechanical engineer who designed this stupid thing...there's no way around having this noodle. There are parts with tight tolerances that fit over it to stiffen things up, but I need to assemble moving parts onto it, and this will be a bearing surface once hardened and nitrided). Part is from maraging 300. I have some ground, but not straightened stock. I also bought some new stock to have straightened then ground (since I think that's the order of operations?) I also don't mind a shop quoting the stock, grinding, and straightening, and said so in my RFQ.

If I have to, I'll buy a used sinker EDM. They run about $40,000 (Plus consumables...ick) in my area with the length capacity for the part. Trying to not spend that much, and not really spend 1/4 of that (since at that point, since I expect to break a lot of these, it would be more worth it to buy the machine so I could make more as I break them!). Looking for 20-30 of these...

Thoughts? Takers on the part? Help?!

. I also am just my own private job shop, so the only RFQ's I've seen are my own

. I also am just my own private job shop, so the only RFQ's I've seen are my own  (small research project) I've probably got something really stupid in this drawing making it so I get no quotes, or no replies. In my RFQ I even specify I'm new at this, and if something looks stupid, talk to me and help me to understand. I get it that most shops are busy now (see the thread with the GBI), so most don't want to take the time to "educate me", but I did figure, for a sinker EDM, this would be an easy job. A bunch of conical divots (seats for conical set screws) and some small holes. I relaxed the tolerances, basically under advice from an EDM dealer, to say I don't need parts run on a CMM afterwards, and I'm asking for more than I need, so if there happens to be a reject in the bunch, I have extras. Any EDM made after about 1995 should be able to hold 0.0002", and the angle tolerances are good for a manual rotary (I think) or a fixture with angles cut in. I figured this would be a "gravy" job (easy, low time, pays well). Only complication would be fixturing, since it is rather long. (Yes, I'm also the idiotic mechanical engineer who designed this stupid thing...there's no way around having this noodle. There are parts with tight tolerances that fit over it to stiffen things up, but I need to assemble moving parts onto it, and this will be a bearing surface once hardened and nitrided). Part is from maraging 300. I have some ground, but not straightened stock. I also bought some new stock to have straightened then ground (since I think that's the order of operations?) I also don't mind a shop quoting the stock, grinding, and straightening, and said so in my RFQ.

(small research project) I've probably got something really stupid in this drawing making it so I get no quotes, or no replies. In my RFQ I even specify I'm new at this, and if something looks stupid, talk to me and help me to understand. I get it that most shops are busy now (see the thread with the GBI), so most don't want to take the time to "educate me", but I did figure, for a sinker EDM, this would be an easy job. A bunch of conical divots (seats for conical set screws) and some small holes. I relaxed the tolerances, basically under advice from an EDM dealer, to say I don't need parts run on a CMM afterwards, and I'm asking for more than I need, so if there happens to be a reject in the bunch, I have extras. Any EDM made after about 1995 should be able to hold 0.0002", and the angle tolerances are good for a manual rotary (I think) or a fixture with angles cut in. I figured this would be a "gravy" job (easy, low time, pays well). Only complication would be fixturing, since it is rather long. (Yes, I'm also the idiotic mechanical engineer who designed this stupid thing...there's no way around having this noodle. There are parts with tight tolerances that fit over it to stiffen things up, but I need to assemble moving parts onto it, and this will be a bearing surface once hardened and nitrided). Part is from maraging 300. I have some ground, but not straightened stock. I also bought some new stock to have straightened then ground (since I think that's the order of operations?) I also don't mind a shop quoting the stock, grinding, and straightening, and said so in my RFQ. If I have to, I'll buy a used sinker EDM. They run about $40,000 (Plus consumables...ick) in my area with the length capacity for the part. Trying to not spend that much, and not really spend 1/4 of that (since at that point, since I expect to break a lot of these, it would be more worth it to buy the machine so I could make more as I break them!). Looking for 20-30 of these...

Thoughts? Takers on the part? Help?!