goldenfab

Cast Iron

- Joined

- May 25, 2016

- Location

- USA Prescott , Arizona

I started reading though the B&A Precision thread. It was really inspiring so I thought I would share my story. To begin with is a lot of backstory hopefully someone finds interesting. If not scroll down a bit and hopefully it gets better...

This all stared when I got my hands on my first screwdriver. I don't remember how old I was but probably not long after getting out of diapers. I would take apart everything I could get my hands on. Of course if it worked before I got a hold of it, it was now ruined. I remember I had boxes upon boxes under my bed where old VCRs and the like went to die. I grew up on a farm and ranch where everything we had seemed like it was at least 20 years old and always broken. I was home schooled and had a lot of free time on the farm so naturally I learned how to fix things and keep them going. I rebuilt old dirt bikes (and blew them up) and gained a lot of hands on experience on the farm with mechanical devices and working with tools. Another big thing that shaped me was building an flying model airplanes. To say I was big into this was an understatement. Turns out this actually benefited me professionally, more on that later.

In high school I got a job in town busing tables at a restaurant. One of the guys that worked at the restaurant and I liked to talk cars like most country boys do. One night after shift we were hanging out in the parking lot by our four wheel drives he was telling me about an article he came across in a magazine that had a design for rotary valve heads for a small block ford with some impressive claims, more on this later. While busing tables I quickly noticed that the waitstaff made considerable more money than I did. Only problem was I was the award shy home-schooled kid who didn't like talking to people, and had a fear of writing down orders. My handwriting was probably as good or better than anyone else working there but I was insecure about people judging it for some reason. I finally decided these two deficiencies were not going to get me where I wanted to go. One morning during the breakfast rush we were understaffed so I picked up some tickets are started taking orders. My boss saw what happened and put me on the schedule as waitstaff that week. I remember a guy that came though from out of state state offered me a job at his auto parts store. He said he saw how I worked and if I ever needed a job he would hire me on the spot. I quickly learned treating people good can make you decent money and opens up doors. About a year later I wrote a check for $6,750 for my first truck, a '92 F-150 4x4 super cab with 117,xxx on the clock. It was just the one I wanted and I still own it to this day.

I remember when taking career placement tests in high school having very strong results showing strong spikes in the engineering, mechanical, and science areas. When it was time to figure out what I was going to do after high school I didn't really question it. I was either going to fly jets or design mechanical things. Both of them required a degree so that is what I was going to get. Neither of my parents went to college but I had everyone's support. I started off at a community college and applied to the Air Force Academy, I was not accepted. During the process of applying someone mentioned if you don't get in check out ERAU. I did and graduated with a BS in Aerospace Engineering. I did mediocre grade wise but went all out in everything I could get into. In fact I was the team leader of our senior design project and graduation class speaker. Remember the part about being the award shy home schooled kid? Well not much has changed but I have fooled a lot of people.

During my time in college I got a job in the machine shop as a 'Lab Monitor'. I was mostly there to yell at people before they did something stupid but I got my feet we in machine work. I started off on a smithy table top mill and small bench top craftsman lathe. I later got checked off on the knee mill and bigger lathe. After getting a taste of machine work I was hooked. Also the idea of a rotary valve head never left me. I would periodically spent long hours at night searching the end of the internet looking at rotary valve head designs and checking on the latest developments of that company. For one of my technical electives for my degree I managed to talk the school into letting me do a directed study for which I would design a rotary valve cylinder head for 2 credit hours. I went out and bought 4hp horizontal shaft engine and designed a rotary valve cylinder head for it. Then for Structures and Instrumentation class where we needed a final project I talked my group into making an engine dyno. We designed and built a engine test stand dyno for the engine. Working in the student machine shop at the school I was able to get most of the machine work on the new head design done but was not able to get it finished before I graduated.

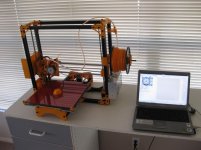

I graduated in 2009 which was not a good time to get a job. In fact after going back to visit my school a year later supposedly there were only two of us out of out senior design team of 13 that had jobs. I was hired by a government subcontractor as a “Test Engineer” for air delivery systems (parachutes) but it was really more about running the test range than engineering. I married and rented a typical 3 bed two car garage house. During this time I exchanged some emails and phone calls with the company that had the rotary valve head design. I was very interested in being a part of bringing the technology to market and eager to work with them. I told them I wanted to see a working prototype I could test out and they were not interested in that. They told me non-exclusive US only patent rights was going to be on the order of several million dollars. After a few more emails with them trying to get them to work with me I gave up on them. Personally I think the whole company is a scam but I was still intrigued by the idea of rotary valve. Not being able to satisfy my taste for engineering or machine work at my day job and still wanting to finish the rotary valve project I bought a used small Grizzly knee mill that was converted to CNC and a manual lathe. I bought Alibre Design that came with a CAM plugin and taught myself CAM. After much work I had a prototype that started and ran but left much to be desired.

Next thing I know my wife has a thing going on with her co-worker. I'll spare you the details but needless to say there was nothing keeping me in town and the sooner I could leave the better. I took some time to re-evaluate life and what is important. The model airplane experience landed me a gig flying UAVs for the military overseas. I sold everything but my truck and machine equipment, tools and some personal items and put them in a storage unit paid up for a year and left the country. I read the Bible cover to cover twice (2nd time minus Psalms), decided what I had been doing before was not working and decided to live a life honoring Christ. I also decided I wanted to make a go of making a rotary valve engine or start some kind of business that included engineering or machine work. Two different co-workers I made friends with convinced me the 4G63 engine would be a great candidate for such a design. I took their advice and bought a used cylinder head off of ebay, had it shipped over and spent the next year drawing up the stock head in CAD and the new rotary valve head design.

I get back to the States a year later and start a new job in Phoenix as a Systems Engineer for a major company working on Flight Management Systems (software side) in business jets. Another year later I marry my now wife. I was a bit more selective this time! We move up near Prescott which made it over an hour drive commute for me. Another year and a half later and our son is to be born. I had a good job and my wife had a better job in Prescott (pharmacist). I tell my boss either I'm going to work part time as will my wife and we'll take turns at home or I may be resigning. Working sometimes as much as 50 hours a week and commuting 2 ¼ hours every day I did not deem good for a new family. I talked everything over with my wife and she was supportive. I had a garage, a plan, savings, and we had our wife's part time income which was enough to keep us afloat. The stage was set and I was going to go on my own!

This all stared when I got my hands on my first screwdriver. I don't remember how old I was but probably not long after getting out of diapers. I would take apart everything I could get my hands on. Of course if it worked before I got a hold of it, it was now ruined. I remember I had boxes upon boxes under my bed where old VCRs and the like went to die. I grew up on a farm and ranch where everything we had seemed like it was at least 20 years old and always broken. I was home schooled and had a lot of free time on the farm so naturally I learned how to fix things and keep them going. I rebuilt old dirt bikes (and blew them up) and gained a lot of hands on experience on the farm with mechanical devices and working with tools. Another big thing that shaped me was building an flying model airplanes. To say I was big into this was an understatement. Turns out this actually benefited me professionally, more on that later.

In high school I got a job in town busing tables at a restaurant. One of the guys that worked at the restaurant and I liked to talk cars like most country boys do. One night after shift we were hanging out in the parking lot by our four wheel drives he was telling me about an article he came across in a magazine that had a design for rotary valve heads for a small block ford with some impressive claims, more on this later. While busing tables I quickly noticed that the waitstaff made considerable more money than I did. Only problem was I was the award shy home-schooled kid who didn't like talking to people, and had a fear of writing down orders. My handwriting was probably as good or better than anyone else working there but I was insecure about people judging it for some reason. I finally decided these two deficiencies were not going to get me where I wanted to go. One morning during the breakfast rush we were understaffed so I picked up some tickets are started taking orders. My boss saw what happened and put me on the schedule as waitstaff that week. I remember a guy that came though from out of state state offered me a job at his auto parts store. He said he saw how I worked and if I ever needed a job he would hire me on the spot. I quickly learned treating people good can make you decent money and opens up doors. About a year later I wrote a check for $6,750 for my first truck, a '92 F-150 4x4 super cab with 117,xxx on the clock. It was just the one I wanted and I still own it to this day.

I remember when taking career placement tests in high school having very strong results showing strong spikes in the engineering, mechanical, and science areas. When it was time to figure out what I was going to do after high school I didn't really question it. I was either going to fly jets or design mechanical things. Both of them required a degree so that is what I was going to get. Neither of my parents went to college but I had everyone's support. I started off at a community college and applied to the Air Force Academy, I was not accepted. During the process of applying someone mentioned if you don't get in check out ERAU. I did and graduated with a BS in Aerospace Engineering. I did mediocre grade wise but went all out in everything I could get into. In fact I was the team leader of our senior design project and graduation class speaker. Remember the part about being the award shy home schooled kid? Well not much has changed but I have fooled a lot of people.

During my time in college I got a job in the machine shop as a 'Lab Monitor'. I was mostly there to yell at people before they did something stupid but I got my feet we in machine work. I started off on a smithy table top mill and small bench top craftsman lathe. I later got checked off on the knee mill and bigger lathe. After getting a taste of machine work I was hooked. Also the idea of a rotary valve head never left me. I would periodically spent long hours at night searching the end of the internet looking at rotary valve head designs and checking on the latest developments of that company. For one of my technical electives for my degree I managed to talk the school into letting me do a directed study for which I would design a rotary valve cylinder head for 2 credit hours. I went out and bought 4hp horizontal shaft engine and designed a rotary valve cylinder head for it. Then for Structures and Instrumentation class where we needed a final project I talked my group into making an engine dyno. We designed and built a engine test stand dyno for the engine. Working in the student machine shop at the school I was able to get most of the machine work on the new head design done but was not able to get it finished before I graduated.

I graduated in 2009 which was not a good time to get a job. In fact after going back to visit my school a year later supposedly there were only two of us out of out senior design team of 13 that had jobs. I was hired by a government subcontractor as a “Test Engineer” for air delivery systems (parachutes) but it was really more about running the test range than engineering. I married and rented a typical 3 bed two car garage house. During this time I exchanged some emails and phone calls with the company that had the rotary valve head design. I was very interested in being a part of bringing the technology to market and eager to work with them. I told them I wanted to see a working prototype I could test out and they were not interested in that. They told me non-exclusive US only patent rights was going to be on the order of several million dollars. After a few more emails with them trying to get them to work with me I gave up on them. Personally I think the whole company is a scam but I was still intrigued by the idea of rotary valve. Not being able to satisfy my taste for engineering or machine work at my day job and still wanting to finish the rotary valve project I bought a used small Grizzly knee mill that was converted to CNC and a manual lathe. I bought Alibre Design that came with a CAM plugin and taught myself CAM. After much work I had a prototype that started and ran but left much to be desired.

Next thing I know my wife has a thing going on with her co-worker. I'll spare you the details but needless to say there was nothing keeping me in town and the sooner I could leave the better. I took some time to re-evaluate life and what is important. The model airplane experience landed me a gig flying UAVs for the military overseas. I sold everything but my truck and machine equipment, tools and some personal items and put them in a storage unit paid up for a year and left the country. I read the Bible cover to cover twice (2nd time minus Psalms), decided what I had been doing before was not working and decided to live a life honoring Christ. I also decided I wanted to make a go of making a rotary valve engine or start some kind of business that included engineering or machine work. Two different co-workers I made friends with convinced me the 4G63 engine would be a great candidate for such a design. I took their advice and bought a used cylinder head off of ebay, had it shipped over and spent the next year drawing up the stock head in CAD and the new rotary valve head design.

I get back to the States a year later and start a new job in Phoenix as a Systems Engineer for a major company working on Flight Management Systems (software side) in business jets. Another year later I marry my now wife. I was a bit more selective this time! We move up near Prescott which made it over an hour drive commute for me. Another year and a half later and our son is to be born. I had a good job and my wife had a better job in Prescott (pharmacist). I tell my boss either I'm going to work part time as will my wife and we'll take turns at home or I may be resigning. Working sometimes as much as 50 hours a week and commuting 2 ¼ hours every day I did not deem good for a new family. I talked everything over with my wife and she was supportive. I had a garage, a plan, savings, and we had our wife's part time income which was enough to keep us afloat. The stage was set and I was going to go on my own!