Way back in early '97, I finally found decent shop space to rent, so I was ready to get started on the machine shop dream.

I was working as a manufacturing engineer for a chain hoist manufacturer (CM Hoist), and had spent the last 7 years cutting my teeth on Mazaks. Right after I started there in '91, we bought our first Mazak, a 6-axis Multiplex with gantry robot loader. Boy, talk about jumping into the deep end!

During my 7 year stint at CM, I purchased some land in a local subdivision, and proceeded to build my own house. I did everything except gradework, framing, and sheetrock. Doing it this way was a major

[email protected]$$, but it allowed me to have the house paid for in 5 years!

(Took about that long to finish it too...I did move in 1 year after starting though...)

Also during this 7 year period, I spent 1 year in Japan, as an "exchange engineer", working and studying Japanese manufacturing methods. And, the biggest change during the 7 years??? I got married.

Anyway, I found the 2000 square foot space, which was part of a larger building, which once housed a very prosperous coal mining machinery repair business. Eventually tax troubles doomed the company, but I believed it was a good omen to have the shop in such hallowed ground.

My strategy was twofold: I was going to get an equity loan on the house, to provide a good cash flow cushion, and then lease 2 brand spanking new Mazaks.

Why brand new?? Well, this was back in '97, and used machine tools were bringing a premium...mainly because of the strong economy. Plus, aside from attending an auction, without the internet, it was pert-near impossible for a bloke like me to find good used cnc equipment for sale. Used dealers were my only option, and they were mighty proud of their machines. Plus, it was almost impossible for a startup to get a big, maybe 6-figure, loan for cnc equipment.

By buying new, I could easily qualify for a lease for two Mazaks.

I had to be very strategic in my house loan/machines lease process.

Why?? Well, I was applying for the house equity loan at the exact same time I was applying for the lease for the new machines. If either bank or leasing company sniffed out the other, I could very likely not get one or the other, or either loan! Without the house loan, I would be cash poor and probably unable to make the lease payments.

But, alas, my timing was perfect.

I got approval for the equity loan, and the machines lease just about the same time!

So, I was going to be proud owner of a brand new SQT15 2-axis cnc lathe, with parts catcher and chip conveyor. And a brand new VTC16-B vertical machining center. The tab? A whopping $193,000!!

Here's the SQT a few years later:

And the VTC:

To be continued....

Greg

(Don't tell the IDA...)

(Don't tell the IDA...)

(Took about that long to finish it too...I did move in 1 year after starting though...)

(Took about that long to finish it too...I did move in 1 year after starting though...)

Why?? Well, I was applying for the house equity loan at the exact same time I was applying for the lease for the new machines. If either bank or leasing company sniffed out the other, I could very likely not get one or the other, or either loan! Without the house loan, I would be cash poor and probably unable to make the lease payments.

Why?? Well, I was applying for the house equity loan at the exact same time I was applying for the lease for the new machines. If either bank or leasing company sniffed out the other, I could very likely not get one or the other, or either loan! Without the house loan, I would be cash poor and probably unable to make the lease payments.

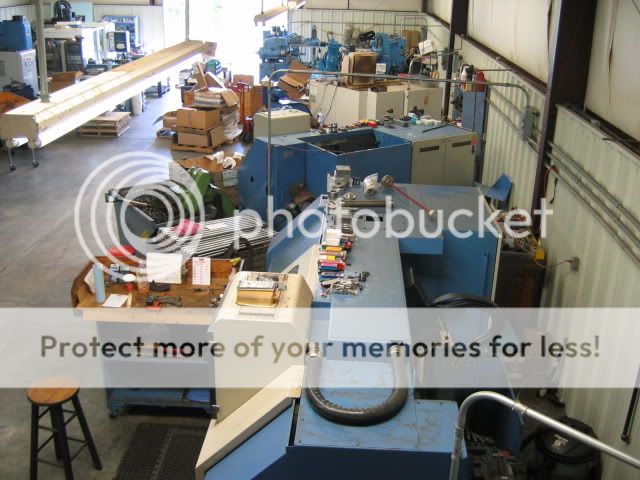

of course, but I had a great plan of how to get me some clients and some work. 4 years later I can say ether I made the right decisions at that time or I was very fortunate. But it sure took a LOT of hard work, fun and hard work (as some of you lucky cats already know). Not too bad now, 4cncs and 3 peeps including myself all tooled up

of course, but I had a great plan of how to get me some clients and some work. 4 years later I can say ether I made the right decisions at that time or I was very fortunate. But it sure took a LOT of hard work, fun and hard work (as some of you lucky cats already know). Not too bad now, 4cncs and 3 peeps including myself all tooled up

also know)

also know)  for myself.

for myself.

):

):