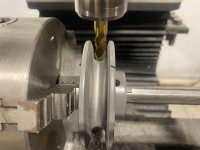

Get yourself a HSS blank, either square or rectangular with a width at least 9/16". A 5/8" blank is probably 4.5 or 5" long, and will mount in a toolpost toolblock with no need for a separate bit holder. Use a bench grinder to put the desired 9/16" diameter profile on the blank. For simplicity, leave the top of the blank unground and mount it as a zero-rake cutter. (Top of the blank at lathe centerline.)

Or, get yourself a sufficiently large brazed carbide cutter with a rectangular profile, say 5/8" wide. Using diamond wheels (rather than green silicon carbide wheels), and preferably using something like a Baldor 500, put the desired 9/16" diameter profile on it. You should rough away the steel shank using normal grinding wheels, before switching to the diamond wheels, as the diamond may be slowly consumed by iron/steel.

Or, get a slightly smaller HSS blank and grind left-hand and right-hand quarter circle profiles on opposite ends of the blank. Or buy two brazed carbide blanks and grind quarter circle profiles on each.