Aryan165

Plastic

- Joined

- Apr 24, 2017

- Location

- United Kingdom

Hi,

I'm looking at this Baldor motor:

Here's the PDF:

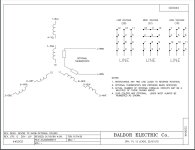

Looking at the product PDF (on the last page) I can't figure out whether it's a Wye or Delta connected motor in the low (220) voltage configuration. I know the drawing is Wye but does that mean it's Wye connected in all the various configurations?

Sorry if it's a stupid question but I'm learning! Any advice is greatly appreciated.

EDIT: Baldor site down right now, here's nameplate and wiring diagram:

I'm looking at this Baldor motor:

Here's the PDF:

Looking at the product PDF (on the last page) I can't figure out whether it's a Wye or Delta connected motor in the low (220) voltage configuration. I know the drawing is Wye but does that mean it's Wye connected in all the various configurations?

Sorry if it's a stupid question but I'm learning! Any advice is greatly appreciated.

EDIT: Baldor site down right now, here's nameplate and wiring diagram:

Last edited: