vonleyser

Cast Iron

- Joined

- Nov 23, 2008

- Location

- Brookshire,Texas USA

I am asking for a bit of help from more knowledgeable on reducing the speed of a driven fan.

I have a Reliance / Baldor 3 phase, 2 HP, model # P14H1446, RPM is 1725.

It came with a Tigear #30A25R14 30 to 1 reducer & a cheap inverter.

The reducer is rather large & heavy by itself, the motor came with a VFD, I bought all 3 pieces as a package deal.

What I would like to accomplish is get rid of the Tigear due to the weight & gear lube being above my head, so either

I purchase, but most likely build some type of a belt drive system to drive an actual Aermotor 8' fan. Going the route of building a pulley system.

This is where I am asking for some ideas on how to actually accomplish my project, I BELIEVE I need to have an approximate

final driven RPM of approximately 50 RPM, if I get close to that I can decrease the speed of the motor with the inverter.

Anyone with ideas of able to draw some type of setup with 2 pulleys or am I going to need 3 or 4 ??

Motor will sit in a vertical position to keep it simple I'm thinking.

On the high note I am even willing to compensate for some help.

Looking online I get a driven 2" pulley along with a ? 69" driven = that doesn't look right to me = I DON'T know

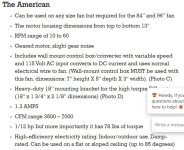

https://wcftexas.com/

They sell ceiling fans but are way out of my price range, ($5000.00 range) and they have not responded to any of my questions & I have sent repeated messages for information. With that type of customer service I don't believe I would or will do business with them.

I have a Reliance / Baldor 3 phase, 2 HP, model # P14H1446, RPM is 1725.

It came with a Tigear #30A25R14 30 to 1 reducer & a cheap inverter.

The reducer is rather large & heavy by itself, the motor came with a VFD, I bought all 3 pieces as a package deal.

What I would like to accomplish is get rid of the Tigear due to the weight & gear lube being above my head, so either

I purchase, but most likely build some type of a belt drive system to drive an actual Aermotor 8' fan. Going the route of building a pulley system.

This is where I am asking for some ideas on how to actually accomplish my project, I BELIEVE I need to have an approximate

final driven RPM of approximately 50 RPM, if I get close to that I can decrease the speed of the motor with the inverter.

Anyone with ideas of able to draw some type of setup with 2 pulleys or am I going to need 3 or 4 ??

Motor will sit in a vertical position to keep it simple I'm thinking.

On the high note I am even willing to compensate for some help.

Looking online I get a driven 2" pulley along with a ? 69" driven = that doesn't look right to me = I DON'T know

https://wcftexas.com/

They sell ceiling fans but are way out of my price range, ($5000.00 range) and they have not responded to any of my questions & I have sent repeated messages for information. With that type of customer service I don't believe I would or will do business with them.

it has exceeded

it has exceeded