hi my friends, i need to drill a .30" diameter deep hole and a friend suggested me to use a D drill. with the gundrill or single flute drill and I could use the geometry of both to have a parameter and make my D bit. I searched for some time here in the forum and I didn't find any model that could be used. So I searched a little more and I found one cad model from a gunsmith named Howie. But I don't know if the cad model is incorrect because it looks like the cutting edge doesn't have any relief at the bottom and appears to be straight. That straight part below the cutting edge won't touch the work first before the cutting edge and will just rub? Can anyone tell if it's correct?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Deep holes drilling

- Thread starter g3nus

- Start date

- Replies 29

- Views 1,573

hvnlymachining

Cast Iron

- Joined

- Jun 21, 2019

- Location

- St.Onge

That type grind is relieved in a special fixture grinding it in a "spiral" pattern, or a continuous axial relief angle.

My understanding of a D bit would make it totally different from a gun drill or a common single flute design.

My understanding of a D bit would make it totally different from a gun drill or a common single flute design.

Last edited:

my idea was to take advantage of the 30° cutting angle and remove the V flute by grinding it halfway. Or replicating that same bit and adding two tubes. I don't know if you can follow my reasoning, as I'm thinking of welding an externally ground tube to the bit, so that I can use a guide bushing and another microtube inside this one connected to the tip of the bit for cooling, as I believe it's something that could be done. Something similar to the attached figure. I could buy a gundrill, but the challenge of doing something new is what inspires me. What do you think?

john.k

Diamond

- Joined

- Dec 21, 2012

- Location

- Brisbane Qld Australia

If you live in the US,you can buy gunsmith special barrels from the likes of Green Mountain for around $30........downgrades because the hole is off centre........and,if you dont live in the US ,then its likely illegal for me to tell you anything about making guns.

hvnlymachining

Cast Iron

- Joined

- Jun 21, 2019

- Location

- St.Onge

The idea sounds possible, but highly flexible. If you've ever used a real gun drill you probably noticed the desire of the drill to twist and chatter until good feeds and speeds are obtained.

I'm afraid a D shape would tend to twist and wander during drilling.

I'm afraid a D shape would tend to twist and wander during drilling.

I don't know if in your last sentence of your reply you were referring to my D-bit design or if you were referring to D-bits in general. And if I was referring to general, I saw an interesting video where a 0.525 hole was drilled in a 32" long 12L14 steel barrel and its deviation was only 0.09". And if I was referring to mine, I also believe that the rod is very fragile and it is very likely that it would twist along the hole. But as I can't stop thinking, I was thinking of grinding a 110° V channel on a rectified bar and also grinding a 3mm channel on the bottom and soldering a microtube connecting to the Bit. However, as I intend to use a guide bushing, I believe that I would have to rectify the V channel so that a V-shaped guide bushing would not have any deviation. Because I believe that a round bushing would make the rod wander without support. And if I decreased the angle to 90°, would the rod still wander in a round guide bushing?

If you live in the US,you can buy gunsmith special barrels from the likes of Green Mountain for around $30........downgrades because the hole is off centre........and,if you dont live in the US ,then its likely illegal for me to tell you anything about making guns.

Hi my friend, I believe the subject I started is not about building guns but building a deep hole drill. Which I believe are different things. As we say in Texas: "If it doesn't help, Dally you tongue!"

trevj

Titanium

- Joined

- May 17, 2005

- Location

- Interior British Columbia

Y'know, if you go looking, you can find more info than you are capable of comprehending, on the geometry of deep hole drills, aka gun drills. Including a lot of verbiage about what angles to dink around with, to accomplish specific needs.

If you do ACTUAL research, rather than just downloading some other guy's work, you will find all this stuff is available and free. You just have to wrap your head around the concepts, and understand them.

If you do ACTUAL research, rather than just downloading some other guy's work, you will find all this stuff is available and free. You just have to wrap your head around the concepts, and understand them.

Freedommachine

Hot Rolled

- Joined

- May 13, 2020

Y'know, if you go looking, you can find more info than you are capable of comprehending, on the geometry of deep hole drills, aka gun drills. Including a lot of verbiage about what angles to dink around with, to accomplish specific needs.

If you do ACTUAL research, rather than just downloading some other guy's work, you will find all this stuff is available and free. You just have to wrap your head around the concepts, and understand them.

Y'know... you could share a link instead of being all

Hi my friend, I believe the subject I started is not about building guns but building a deep hole drill. Which I believe are different things. As we say in Texas: "If it doesn't help, Dally you tongue!"If you live in the US,you can buy gunsmith special barrels from the likes of Green Mountain for around $30........downgrades because the hole is off centre........and,if you dont live in the US ,then its likely illegal for me to tell you anything about making guns.

I'm using Howe's work as a reference, because probably one of the greatest gunsmiths in the USA was humble enough to share his work, instead of wasting his time to lecture others. I would love to use your work as a reference, if you have them, of course!Y'know, if you go looking, you can find more info than you are capable of comprehending, on the geometry of deep hole drills, aka gun drills. Including a lot of verbiage about what angles to dink around with, to accomplish specific needs.

If you do ACTUAL research, rather than just downloading some other guy's work, you will find all this stuff is available and free. You just have to wrap your head around the concepts, and understand them.

hvnlymachining

Cast Iron

- Joined

- Jun 21, 2019

- Location

- St.Onge

Well, as a curious guy myself, I say give it a try. As long as you don't have a customer beating your door down to get it done in a hurry it'll be a good project to learn from. That's how things progress.

michiganbuck

Diamond

- Joined

- Jun 28, 2012

- Location

- Mt Clemens, Michigan 48035

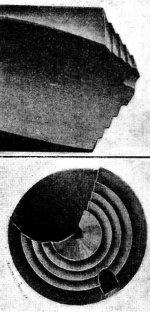

Single and double flute gun drills act like a reamer with having a margin at the OD and often a following margin at the heel of the OD so as to become a self-guiding tool for very high-quality straightness.

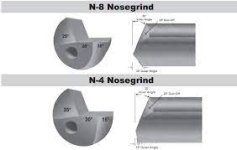

Continued radial relief is common end grinding with the likes of an Eldorado fixture, but a slash grid at 10-12 * Clearance is Ok, followed by perhaps a 20* secondary to a land..and then a butterfly grind to roll the heel away. Most that I have sharpened did not cut to the center but followed a pre-drilled hole. Not uncommon to have high pressure coolant to flush out chips.

Continued radial relief is common end grinding with the likes of an Eldorado fixture, but a slash grid at 10-12 * Clearance is Ok, followed by perhaps a 20* secondary to a land..and then a butterfly grind to roll the heel away. Most that I have sharpened did not cut to the center but followed a pre-drilled hole. Not uncommon to have high pressure coolant to flush out chips.

Last edited:

michiganbuck

Diamond

- Joined

- Jun 28, 2012

- Location

- Mt Clemens, Michigan 48035

QT Op: (because it looks like the cutting edge doesn't have any relief at the bottom and appears to be straight.)

That looks like a circle grind, but actually is a radial relief grind as if the tool end was axially pushed to the wheel with a screw thread movement. the cutting edge is highest and all after the cutting edge is falling away at a rate of 10 to 12 decrees.

If you look at the very edge corner from the OD position with a loupe you will see about 12* clearance.

That looks like a circle grind, but actually is a radial relief grind as if the tool end was axially pushed to the wheel with a screw thread movement. the cutting edge is highest and all after the cutting edge is falling away at a rate of 10 to 12 decrees.

If you look at the very edge corner from the OD position with a loupe you will see about 12* clearance.

Last edited:

Hi friend, how are you? I decided to accept my friend Trevi's proposal and study more about gundrill and you don't mind, I would like to discuss this with you a little more. What I Learned: Gundrill is the successor to the D-bit drill with some innovations, such as a tube for tip cooling. It is also a bit that cuts on one side, but with two cutting edges, an input edge and an output edge. The apex is directed at 1/4 of the center of the bit diameter, so you can add two edges. With this information, I started to think about the following: Does the smaller angle and larger area of the entrance edge serve to have greater resistance on the right part of the bit and compensate for the natural tendency of the bit to move to the left? And I didn't find information about the wedge angle, that front relief below the cutting edge. How much would be indicated, about 10%? 20%?QT Op: (because it looks like the cutting edge doesn't have any relief at the bottom and appears to be straight.)

That looks like a circle grind, but actually is a radial relief grind as if the tool end was axially pushed to the wheel with a screw thread movement. the cutting edge is highest and all after the cutting edge is falling away at a rate of 10 to 12 decrees.

If you look at the very edge corner from the OD position with a loupe you will see about 12* clearance.

trevj

Titanium

- Joined

- May 17, 2005

- Location

- Interior British Columbia

Deep Hole drilling has more written about it than many machining subjects, and if you are too lazy to do some actual homework, you deserve the results you end up with, which by the looks of the way you go on, is gonna be craptastic.Hi my friend, I believe the subject I started is not about building guns but building a deep hole drill. Which I believe are different things. As we say in Texas: "If it doesn't help, Dally you tongue!"

I'm using Howe's work as a reference, because probably one of the greatest gunsmiths in the USA was humble enough to share his work, instead of wasting his time to lecture others. I would love to use your work as a reference, if you have them, of course!

Howe was a good gunsmith 100 years or so ago. Technology has moved on. Tools, materials, and methods, have evolved that Howe never dreamed of. Using Howe as your reference is like using Henry Ford's Model T as your source for auto repair.

Unless you happen to have the means to form the vee groove down the side of a tube, or bore a coolant hole down the length of a shank that has the vee machined out of it already, you are peeing well into the wind. It may give you a warm all over feeling, but the end result is you just get covered in the stuff.

Buy a drill. They are cheap for what you get, and cheaper still if you shop the poverty source, ebay, for used, and jig up to resharpen them. Guhrig, Sterling, and just about every other supplier of gun drills has LOTS of data online to read through.

michiganbuck

Diamond

- Joined

- Jun 28, 2012

- Location

- Mt Clemens, Michigan 48035

On a single flute gun drill only one flute end cuts on the part, the other flute end (opposite) is way below the end of the cutter and does no cutting.

A double flute is one with both end-cutting edges are engaged.

One huge difference between gun drills and conventional is that gun drills have multiple circle grind OD diameter lands that make the cutter OD act like it is carrying its alignment bushing as it penetrates the bore.

www.bing.com

www.bing.com

A gun drill is not the same as a chambering remer

A double flute is one with both end-cutting edges are engaged.

One huge difference between gun drills and conventional is that gun drills have multiple circle grind OD diameter lands that make the cutter OD act like it is carrying its alignment bushing as it penetrates the bore.

gun drill geometry - Bing

Find high-quality images, photos, and animated GIFS with Bing Images

A gun drill is not the same as a chambering remer

Hi friends, I found a repost of a classic deep hole drilling. It contains a lot of cool information and some drawings of what I believe to be one of the first gundrills. Which they called D drill. Very ugly by the way! lol I hope the ADM doesn't mind if I post links here.

https://archive.org/details/deepholedrillingbymachinerymagazine/mode/1up

Look this

https://archive.org/details/deepholedrillingbymachinerymagazine/mode/1up

Look this