RCPDesigns

Hot Rolled

- Joined

- Sep 3, 2014

- Location

- Atlanta GA.

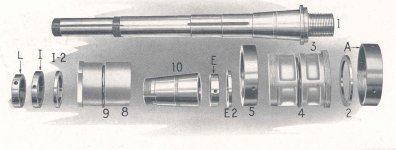

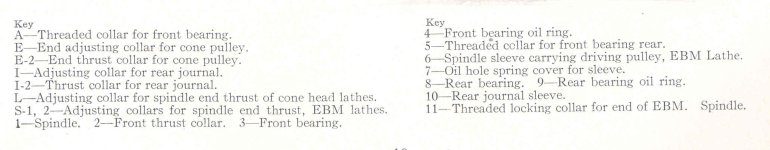

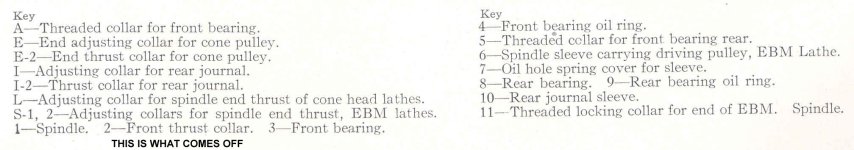

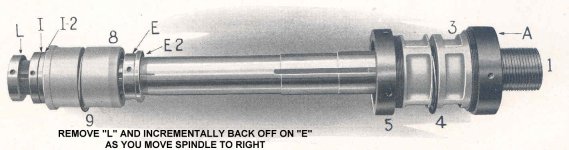

I have a Hendey-Norton 1B Universal mining machine that I'm restoring. It has a stuck spindle. I believe Hendeyman said the spindle section (it has a tapered spindle) was just like the lathe. I have a picture of the headstock and the instructions for removing the spindle but they reference collar A, guard K, collar L, collar E, etc, etc but the picture doesn't have (or I can't see) any labels. I think the PDF I'm referencing is John's best copy, but maybe there is one that has the labels? https://pounceatron.dreamhosters.com/docs/hendey/1920-Hendey-manual.pdf