tonylathes

Aluminum

- Joined

- Oct 31, 2009

- Location

- UK

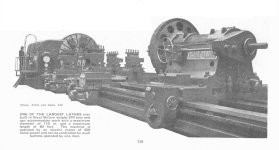

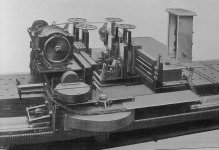

Too big to fit into our sheds and garages, but an interesting catalogue from the 1930s? Oddly, the original pages had rather small images but, scanned at 800 d.p.i., they have blown up pretty well

Noble & Lund Large Machine Tools

Founded in 1886 by Harry Noble and Pearson Lund, Noble & Lund was based in Felling-on-Tyne, Gateshead. Success appear to have been almost immediate with, by 1899, shares being issued and the company going public - though by 1908 it was back in private han

www.lathes.co.uk