Jefflevine

Plastic

- Joined

- Mar 25, 2016

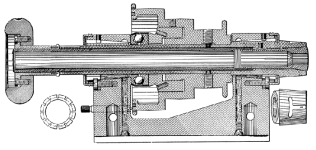

Hello Folks, I recently noticed a small amount of oil seeping from the right side of my plain-bearing Cataract 47 headstock pulley, as shown in the attached pic.

The lathe is working well, with no unusual noises or vibration.

The only recent change I made to the setup was adding a belt tensioner.

Should I be concerned? Any investigatory/remedial steps I should take?

Thanks,

Jeff

The lathe is working well, with no unusual noises or vibration.

The only recent change I made to the setup was adding a belt tensioner.

Should I be concerned? Any investigatory/remedial steps I should take?

Thanks,

Jeff