Hi,

I am starting scraping grey continuous cast 1-1/4x2" straight edge. Will the weight difference spotting the angled face be an issue as I progress? Should I lift up on it? I don't really want to lighten the overhang size, but I could if worthwhile.

Comparing spotting between straight edge sitting directly on plate and spotting slightly lifting up on the heavy side it's similar contact points, just less pronounced towards the knife edge. It seems like it would be better to spot it natural resting position but I am not sure.

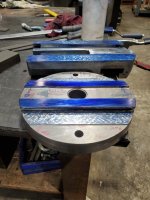

Lifting up on the heavy side:

Straight on plate pushing with bolts in end.

Thanks,

Will.

I am starting scraping grey continuous cast 1-1/4x2" straight edge. Will the weight difference spotting the angled face be an issue as I progress? Should I lift up on it? I don't really want to lighten the overhang size, but I could if worthwhile.

Comparing spotting between straight edge sitting directly on plate and spotting slightly lifting up on the heavy side it's similar contact points, just less pronounced towards the knife edge. It seems like it would be better to spot it natural resting position but I am not sure.

Lifting up on the heavy side:

Straight on plate pushing with bolts in end.

Thanks,

Will.