arsenix

Plastic

- Joined

- Jul 28, 2011

- Location

- Milpitas, CA

I've looked through the many (dozens?) of different low speed lapping machines folks have come up with. The "legit" ones are too pricey for my taste, and I was hoping to come up with an easy way to sharpen scraping blades that doesn't take up a lot of room in the shop and that I can put away easily when I'm not using. My idea, maybe a silly one, is to built a little rig to spin diamond lapping plates at slow speeds that bolts up to a standard bench grinder. I (like many I'm sure) have a handful of bench grinders kicking around so this seems like a decent idea?

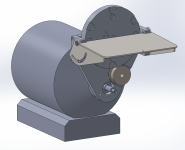

I did some fooling around in CAD and came up with this initial design. Has a few CNC aluminum plates for the bracketry and an aluminum disk for the lapping plate holder. A single sealed bearing is used as the low speed spindle. A flat belt running around the grinder spindle and the outside of the lapping spindle gives a reduction of 12:1. A few laser cut steel plates welded together are used as the work surface, and can be tilted up 30 degrees or down 80 degrees (my idea there is that it can fold all the way down for flat storage). Like several others online I was thinking the diamond plates could be held on by magnets. Given the low forces I was thinking the magnets alone would be fine to hold it in place and stop it from slipping?

I haven't modeled all the hardware although it should all be stock items. I found a cheap idler pulley on amazon which is modeled in here as a simple fixed tensioner. If I could find an appropriate soft rubber vacuum cleaner belt I suppose I could just stretch it on and go without a tensioner.

This is sized to fit a cheap (terrible in fact) 6" chinese bench grinder I had sitting gathering dust. It has 3x 8-32 threaded holes on a 2" circle on the end for mounting the wheel guard. I have no idea how standard this is. Ideally this would fit a multitude of different bench grinders.

Thoughts, criticism? If this worked maybe I could do a run of parts kits for folks to make their own and/or open source the design. There doesn't seem to be a straightforward way to DIY such a thing currently.

I did some fooling around in CAD and came up with this initial design. Has a few CNC aluminum plates for the bracketry and an aluminum disk for the lapping plate holder. A single sealed bearing is used as the low speed spindle. A flat belt running around the grinder spindle and the outside of the lapping spindle gives a reduction of 12:1. A few laser cut steel plates welded together are used as the work surface, and can be tilted up 30 degrees or down 80 degrees (my idea there is that it can fold all the way down for flat storage). Like several others online I was thinking the diamond plates could be held on by magnets. Given the low forces I was thinking the magnets alone would be fine to hold it in place and stop it from slipping?

I haven't modeled all the hardware although it should all be stock items. I found a cheap idler pulley on amazon which is modeled in here as a simple fixed tensioner. If I could find an appropriate soft rubber vacuum cleaner belt I suppose I could just stretch it on and go without a tensioner.

This is sized to fit a cheap (terrible in fact) 6" chinese bench grinder I had sitting gathering dust. It has 3x 8-32 threaded holes on a 2" circle on the end for mounting the wheel guard. I have no idea how standard this is. Ideally this would fit a multitude of different bench grinders.

Thoughts, criticism? If this worked maybe I could do a run of parts kits for folks to make their own and/or open source the design. There doesn't seem to be a straightforward way to DIY such a thing currently.