Hi Everyone!

Well, here I am again. For those of you who don’t recognize the latest user-name, I’m Nelson Timken. I’ve been banned from this forum many, many times, but I enjoy forcing myself in where I’m not wanted. You would think I would have enough self-respect to just move on, but I guess not. How am I able to keep intruding here even after being banned? I’m very clever: I googled “ISP-masking software”, and VOILA! I simply make up another inane user-name and here I am. (I'm a lawyer, by the way.) In your face, Practical Machinist!

I don’t like the moderator, Paula, because she stands up to me, and I HATE it when people try to make me follow the rules. Plus, I can’t seem to drag her down to my level, so I get even more frustrated. I can be very nice most of the time -- almost nauseatingly saccharine -- but if you cross me, if I even

suspect you’ve crossed me, or if you refuse to hate the same people I’ve decided to hate, etc., etc., look out! I’ll hound you ‘til the day you die.

Since I seem to keep getting booted off the larger forums, my tantrums are being restricted to smaller and smaller venues (everyone else is the problem -- not me.) As a hedge against my eventual expulsion from Yahoo! and HSM, I’ve started my own forum where *I* make the rules:

www.nutcase.com

C’mon join up, and let’s see how long I before I start kicking everyone off...

See ya later!

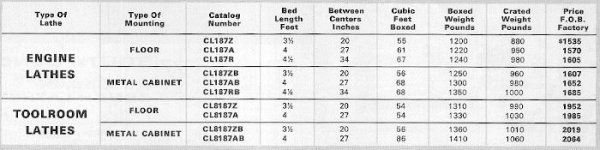

I almost quatted a kidney trying to shove the lathe a few inches. I think I will weld up a rolling platform with caster wheels to move the lathe when necessary. I was wondering what the approximate weight is so I can source the properly rated wheels to handle the weight. I think adding four leveling screws on the corners will alleviate the wheels when the machine is stationary. I haven't yet figured out a way to build retractable wheels or else I could go that route.

I almost quatted a kidney trying to shove the lathe a few inches. I think I will weld up a rolling platform with caster wheels to move the lathe when necessary. I was wondering what the approximate weight is so I can source the properly rated wheels to handle the weight. I think adding four leveling screws on the corners will alleviate the wheels when the machine is stationary. I haven't yet figured out a way to build retractable wheels or else I could go that route.

I have a 1943 heavy 10 cast iron pedestal and legs.

I have a 1943 heavy 10 cast iron pedestal and legs.  .

.