texasgeartrain

Titanium

- Joined

- Feb 23, 2016

- Location

- Houston, TX

I've been working a job a few hours from my home shop. Working a ton of OT, plus spending an average of half my week away from home. Its put a serious damper on my own projects and home shop. Plus while away, I've had a few occasions where I could use my machine tools, and not having them readily available has become a real pita.

I've considered moving some of my machines down to the Corpus Christie area, but ultimately, I'm not going to relocate or give up my home or shop in the Houston area. My Monarch Series 61 is still my priority project at home, I've just not had the time to dive into while there. Hopefully soon, as I clear work and add more people to the job in the Corpus area.

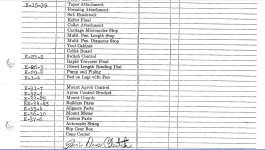

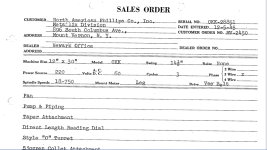

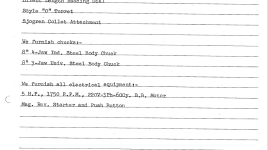

All this has led me to wanting to add a machine or two ( ) in the Corpus shop. I had been casually looking for another Series 61, Pacemaker, or Pratt & Whitney Model C. I came across a Monarch 12CKK at HGR that was fairly cheap, due to a broken coupling at qcgb for the clutch lever. This looked like a relativly easy fix for me. Not a toolroom lathe, but has taper attachment and leadscrew reverse just above qcgb. I was thinking this could be be a decent purchase, and handle basic work for me. So I bought it.

) in the Corpus shop. I had been casually looking for another Series 61, Pacemaker, or Pratt & Whitney Model C. I came across a Monarch 12CKK at HGR that was fairly cheap, due to a broken coupling at qcgb for the clutch lever. This looked like a relativly easy fix for me. Not a toolroom lathe, but has taper attachment and leadscrew reverse just above qcgb. I was thinking this could be be a decent purchase, and handle basic work for me. So I bought it.

Some Pics from the HGR advert:

I've considered moving some of my machines down to the Corpus Christie area, but ultimately, I'm not going to relocate or give up my home or shop in the Houston area. My Monarch Series 61 is still my priority project at home, I've just not had the time to dive into while there. Hopefully soon, as I clear work and add more people to the job in the Corpus area.

All this has led me to wanting to add a machine or two (

) in the Corpus shop. I had been casually looking for another Series 61, Pacemaker, or Pratt & Whitney Model C. I came across a Monarch 12CKK at HGR that was fairly cheap, due to a broken coupling at qcgb for the clutch lever. This looked like a relativly easy fix for me. Not a toolroom lathe, but has taper attachment and leadscrew reverse just above qcgb. I was thinking this could be be a decent purchase, and handle basic work for me. So I bought it.

) in the Corpus shop. I had been casually looking for another Series 61, Pacemaker, or Pratt & Whitney Model C. I came across a Monarch 12CKK at HGR that was fairly cheap, due to a broken coupling at qcgb for the clutch lever. This looked like a relativly easy fix for me. Not a toolroom lathe, but has taper attachment and leadscrew reverse just above qcgb. I was thinking this could be be a decent purchase, and handle basic work for me. So I bought it.Some Pics from the HGR advert:

Last edited: