You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

American Pacemaker lathe 1950 25x216, electric brake info

- Thread starter Kenneth B

- Start date

- Replies 31

- Views 1,999

Here is a large list of resources. You should be able to find your lathe.

Here

The clutch and brake are mechanical on Pacemakers up to 20".

Larger lathe's may be different.

Here

The clutch and brake are mechanical on Pacemakers up to 20".

Larger lathe's may be different.

hvnlymachining

Cast Iron

- Joined

- Jun 21, 2019

- Location

- St.Onge

American Pacemaker with electric brake? Share a picture please. Those of us in the Pacemaker owners club would like to have a look. One of the whole lathe might be nice too!

This is what you should have.

Most other larger lathes also use a clutched spindle and brake. The motor runs all the time. Big motors are often only rated a couple starts an hour.

Most other larger lathes also use a clutched spindle and brake. The motor runs all the time. Big motors are often only rated a couple starts an hour.

Thanks for all the interest and responses.

I don't have a picture of the Brake assembly because it is inside the Spindle Sheave pulley. The only view of it is through a small cover where the 2 power wires are connected. Shown in upper right of photo. I believe it should be powered by DC voltage, nut I have no data label off the brake itself, I do have an old electrical drawing that is not for this exact lathe, which shows a DC power supply for the brake. Don't know the voltage or current required.

I don't have a picture of the Brake assembly because it is inside the Spindle Sheave pulley. The only view of it is through a small cover where the 2 power wires are connected. Shown in upper right of photo. I believe it should be powered by DC voltage, nut I have no data label off the brake itself, I do have an old electrical drawing that is not for this exact lathe, which shows a DC power supply for the brake. Don't know the voltage or current required.

hvnlymachining

Cast Iron

- Joined

- Jun 21, 2019

- Location

- St.Onge

I'm not familiar with this model, we've got two similar but smaller lathes, but I noticed a lack of clutch control rod. I may be wrong, but it looks like it has an electric clutch/ brake. Meaning the clutch is electric as well.

hvnlymachining

Cast Iron

- Joined

- Jun 21, 2019

- Location

- St.Onge

Well.... Looks like may be wrong Accord to the bulletin you posted.

By the way, beautiful machine you have there!

By the way, beautiful machine you have there!

Kenneth B

Did you verify the year of your lathe by the serial number? It's on the vertical surface of the front way all the way to the tailstock end.

It will be in this format. 74093 /54, The 54 on the end is the year. You may already know this, but I have searched literature from 1949 to 53 and don't see electric brake option. That doesn't mean it's not out there. You have it.

Verify the year.

You should have the D.C. transformer for the brake in your electrical panel.

Did you verify the year of your lathe by the serial number? It's on the vertical surface of the front way all the way to the tailstock end.

It will be in this format. 74093 /54, The 54 on the end is the year. You may already know this, but I have searched literature from 1949 to 53 and don't see electric brake option. That doesn't mean it's not out there. You have it.

Verify the year.

You should have the D.C. transformer for the brake in your electrical panel.

Last edited:

Read the specs on these similar Warner brakes.

90vdc as Thermite says.

I googled {American Pacemaker Lathe Electric brake} and got pages of warner brakes. Not yours but in the same family.

https://www.zoro.com/warner-electri...-90vdc-cbc-150-1/i/G1492854/?recommended=true

90vdc as Thermite says.

I googled {American Pacemaker Lathe Electric brake} and got pages of warner brakes. Not yours but in the same family.

https://www.zoro.com/warner-electri...-90vdc-cbc-150-1/i/G1492854/?recommended=true

Last edited:

These brakes bring to mind while working as a machine adjuster setting up envelope folding machines.

They had a new brake unit installed to keep constant drag on the web. It held tension on the #1,000 roll of paper.

The constant squeaking was annoying. A guy decided to oil the rotor. He got a large butt chewing and left for other employment.

Bill

All I see is 90v. I'm curious as to what Kenneth's brake problem is, hungry for details I'm guessing its dead. Hopefully not the internal coil. That could be hard to find.

I like the manual clutch/brake setup.

Kenneth

Posting details of the issue helps diagnose and may help a future member with the same issue.

Thats a really nice lathe you have. We're learning of another optional feature. I shouldn't say we. Me is

They had a new brake unit installed to keep constant drag on the web. It held tension on the #1,000 roll of paper.

The constant squeaking was annoying. A guy decided to oil the rotor. He got a large butt chewing and left for other employment.

Bill

All I see is 90v. I'm curious as to what Kenneth's brake problem is, hungry for details I'm guessing its dead. Hopefully not the internal coil. That could be hard to find.

I like the manual clutch/brake setup.

Kenneth

Posting details of the issue helps diagnose and may help a future member with the same issue.

Thats a really nice lathe you have. We're learning of another optional feature. I shouldn't say we. Me is

I really appreciate all the good advice and info.

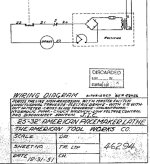

I'm attaching closest electrical drawing that I was able to get from Bourn & Koch Inc.-which supply some parts for these old machines;

NOT for the exact 1950 model( SN 17950-50) that we have.

My goal was to identify what type of power supply I would need to make the electric Spindle brake work.

I think the brake coil is good, its reads 274 ohms.

I've never seen a working unit , the shop just got the lathe recently, and didn't get the electrical controls with it.

If the unit is consistent with the drawing, then it is intended to be DC powered. I tend to agree with the previous comments that switching the AC side seems like a better method theatrically, but I also read 'somewhere' that switching on the DC side may provide faster operation so the brake isn't delayed anymore than necessary as the motor is turning on. The brake is deenergized upon spindle startup. Looks like the maker choose DC switching.

Any thoughts on how robust of a contact one would need to switch it?

I don't image it's very much current? Would an Aux contact on the spindle motor contactor be sufficient ?

Sounds like maybe I should try 90Vdc, and see if it works. Thanks for the links to supplies !!

My Googles had not turned those up. I wonder if you guys having searched for lathe info more than I , if Google serves you up better results than I got?

I notice the drawing shows a variable DC supply, any thoughts on what that was used for?

Any thoughts on how much need there is for a brake, does the gearing provide much braking on these lathes?

I know that's a lot of questions .

Thanks again !

I'm attaching closest electrical drawing that I was able to get from Bourn & Koch Inc.-which supply some parts for these old machines;

NOT for the exact 1950 model( SN 17950-50) that we have.

My goal was to identify what type of power supply I would need to make the electric Spindle brake work.

I think the brake coil is good, its reads 274 ohms.

I've never seen a working unit , the shop just got the lathe recently, and didn't get the electrical controls with it.

If the unit is consistent with the drawing, then it is intended to be DC powered. I tend to agree with the previous comments that switching the AC side seems like a better method theatrically, but I also read 'somewhere' that switching on the DC side may provide faster operation so the brake isn't delayed anymore than necessary as the motor is turning on. The brake is deenergized upon spindle startup. Looks like the maker choose DC switching.

Any thoughts on how robust of a contact one would need to switch it?

I don't image it's very much current? Would an Aux contact on the spindle motor contactor be sufficient ?

Sounds like maybe I should try 90Vdc, and see if it works. Thanks for the links to supplies !!

My Googles had not turned those up. I wonder if you guys having searched for lathe info more than I , if Google serves you up better results than I got?

I notice the drawing shows a variable DC supply, any thoughts on what that was used for?

Any thoughts on how much need there is for a brake, does the gearing provide much braking on these lathes?

I know that's a lot of questions .

Thanks again !

Attachments

hvnlymachining,I'm not familiar with this model, we've got two similar but smaller lathes, but I noticed a lack of clutch control rod. I may be wrong, but it looks like it has an electric clutch/ brake. Meaning the clutch is electric as well.

I'm just learning about this unit, but I don't see anything else that would require wiring; so I don't think there is an electrical clutch.

I do know the spindle operated without any power on the brake, as I bumped the spindle motor and it runs and the chuck turned.

This is the electrical panel on my 1952 Pacemaker. This may help you get started.

I believe my electrical box is unmolested. I know you have rapids and the electric brake making yours a little more work.

Anything you need help with here let me know. It's a pretty basic start, stop. setup.

Edit; You may also have a coolant pump circut to add. You sound like your very capable.

I believe my electrical box is unmolested. I know you have rapids and the electric brake making yours a little more work.

Anything you need help with here let me know. It's a pretty basic start, stop. setup.

Edit; You may also have a coolant pump circut to add. You sound like your very capable.

Last edited:

m-lud .

Thanks for the photo. Love the original A-B equipment, still in service ! I guess the alloy contacts were so new, they felt the need to print directions on the front. I wonder what the A-B CAT# was on that. Looks like someone noted on the fuses they are 60A .

Thanks for the photo. Love the original A-B equipment, still in service ! I guess the alloy contacts were so new, they felt the need to print directions on the front. I wonder what the A-B CAT# was on that. Looks like someone noted on the fuses they are 60A .

The machine came from a plant equipment auction, and no electrical box. I have an electrical drawing of similar lathe by ATW. I can handle the starter electrical box. The brake circuit has been the unknown, but I think you all have help me get a idea what direction to go.

Similar threads

- Replies

- 14

- Views

- 827