Turbinator

Plastic

- Joined

- Nov 15, 2022

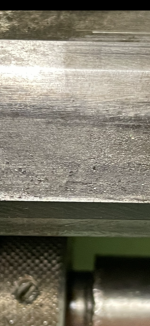

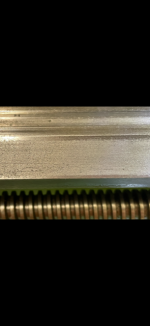

Good day to you all, I’m new here and could do with some advice on how to proceed with a weiler Ergodor rebuild I’m carrying out. The ways look very strange, almost like they have been eaten by acid or some other corrosive material. Have a look and let me know what you think. I’m in Finland and finding somewhere to regrind the bed is nigh on impossible…:/