AlfaGTA

Diamond

- Joined

- Dec 13, 2002

- Location

- Benicia California USA

Got a little job here.

Meed to modify the bearing bores for the output axle bearings on a "Hewland" transaxle side cover.

Not a real complex job but takes some thought on the setup.

Covers are cast mag. and the outside surface is pretty much as cast.....no reference surfaces.

There are mounting bolt holes that are spot faced, but not necessarily all the same or referenced to anything else.

Here is my solution........

Setup with a vise , rotate the table 90* to get the vise orientated.(Jaws running parallel with the "Y")

Set the machine to run horizontal.

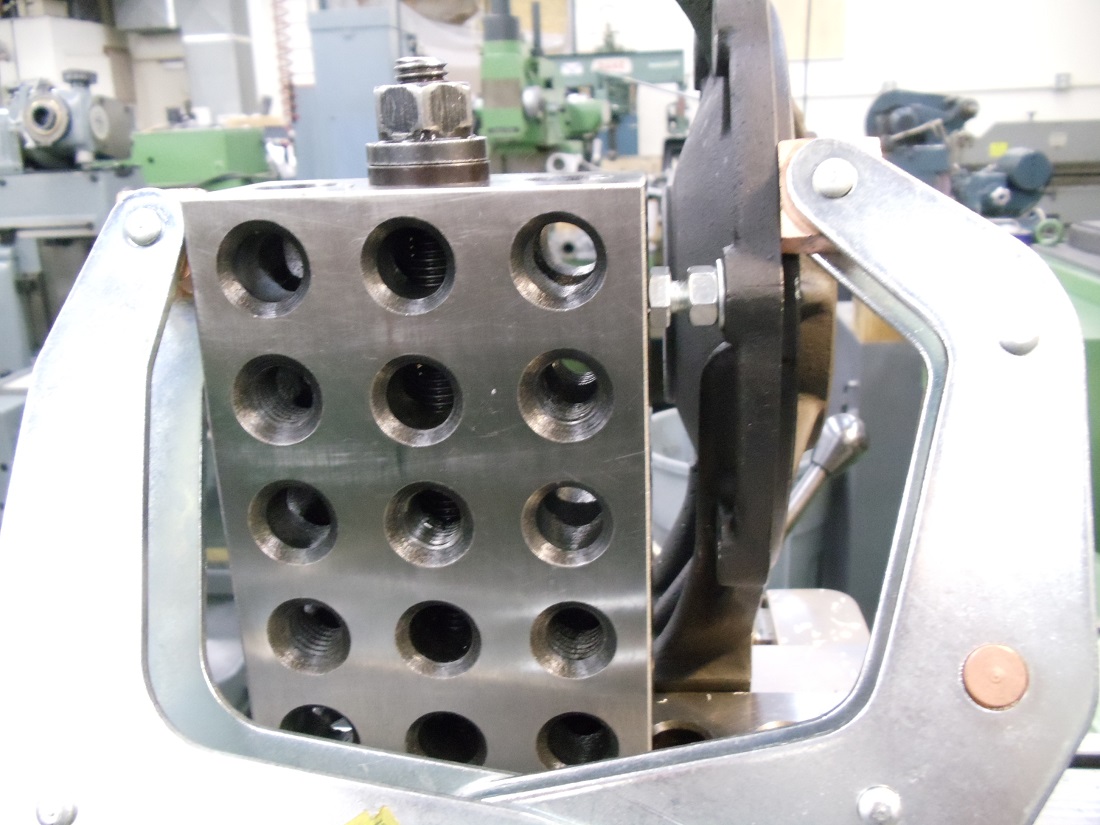

Clamp a 2-4-6 block (valuable to have 1-2-3 blocks as well as 2-4-6 blocks when running horizontal)

Use additional 2-4-6 set vertical making a make shift square.....Hold with redi-rod and nuts (1/2-13, same as the hold down tooling i use)

Some things to note: Cover is bolted through an existing part of the casting using a 1/2 " thread passes through the casting (suspension anchor point) and through the 2-4-6 block.

I adjust the vertical square of the part using a 5/16" bolt and nut between one of the cover mounting holes and the vertical 2-4-6. All held as adjusted using a "Kant-Twisr" clamp.....

Back side view of holding bolt....and vertical 2-4-6 block.....

Alignment in the "X" plane is done by rotating the table.....pretty darn nice accessory IMO

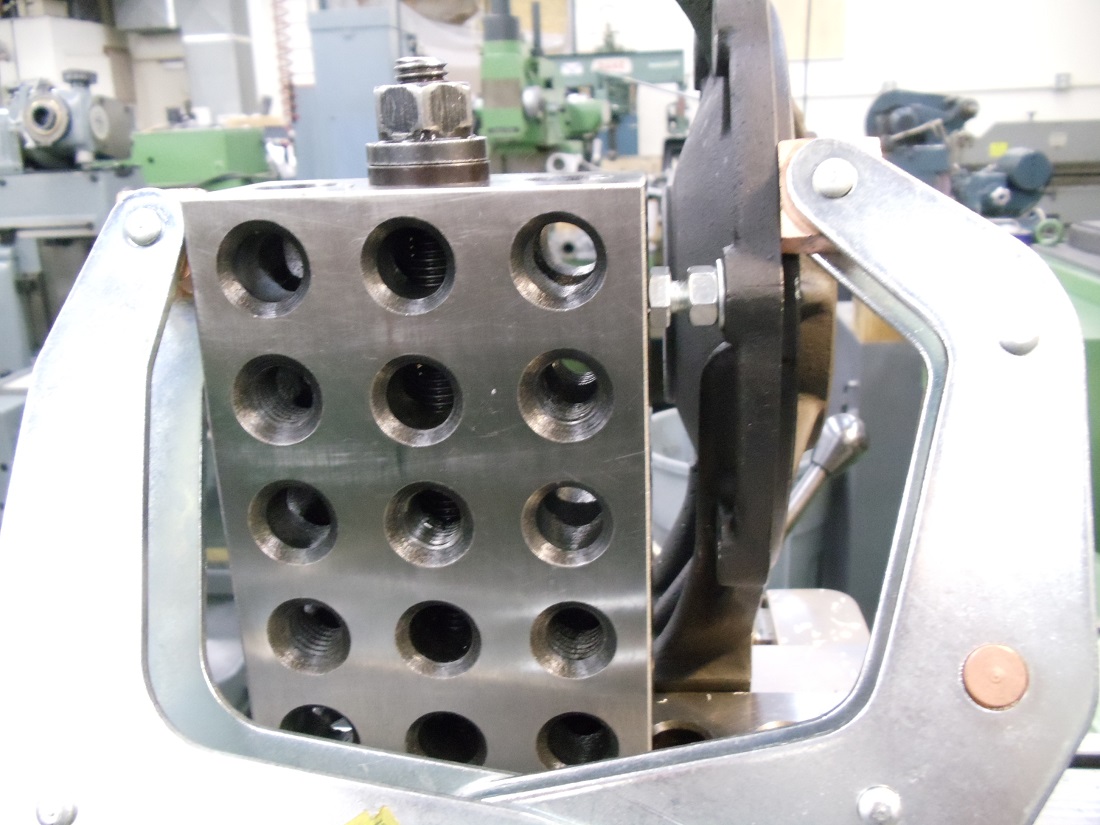

Boring setup is Sandvik "Capto" fine boring head.....some of the nicest kit i have...

Close up of the adjuster for the vertical ......

Cheers Ross

Meed to modify the bearing bores for the output axle bearings on a "Hewland" transaxle side cover.

Not a real complex job but takes some thought on the setup.

Covers are cast mag. and the outside surface is pretty much as cast.....no reference surfaces.

There are mounting bolt holes that are spot faced, but not necessarily all the same or referenced to anything else.

Here is my solution........

Setup with a vise , rotate the table 90* to get the vise orientated.(Jaws running parallel with the "Y")

Set the machine to run horizontal.

Clamp a 2-4-6 block (valuable to have 1-2-3 blocks as well as 2-4-6 blocks when running horizontal)

Use additional 2-4-6 set vertical making a make shift square.....Hold with redi-rod and nuts (1/2-13, same as the hold down tooling i use)

Some things to note: Cover is bolted through an existing part of the casting using a 1/2 " thread passes through the casting (suspension anchor point) and through the 2-4-6 block.

I adjust the vertical square of the part using a 5/16" bolt and nut between one of the cover mounting holes and the vertical 2-4-6. All held as adjusted using a "Kant-Twisr" clamp.....

Back side view of holding bolt....and vertical 2-4-6 block.....

Alignment in the "X" plane is done by rotating the table.....pretty darn nice accessory IMO

Boring setup is Sandvik "Capto" fine boring head.....some of the nicest kit i have...

Close up of the adjuster for the vertical ......

Cheers Ross