Hi guys!

I've posted before, but finally, I arrived at the machinists' league.

I got an 1989 MAHO MH500M model for a very fair price. It is a late manual model with basic Heidenhain DRO, no rapids, Variator feed and speed selection. I think the rapid feed version came around 1990.

It is believed to have few running hours, came from a pneumatic manufacturer's in-house repair facility. The cosmetic flaking is almost untouched on the head and cross slides. Only little wear shows on the edge of the vertical flat ways where the heavy column rides. It has tilting table, so I plan to compensate most of the sagging, if exists.

More pics: Google drive link (sorry, too high res pics)

I believe there are some forum members who had machines like these, so if you see it, your advice is welcomed!

It needs some TLC, but otherwise ready for action. My biggest sorrow is that the original plastic oil fill and drain reservoirs are cracked thus leaking some oil. These pieces are unobtainable, of course.

My first question would be, Is lifetime-lubrication means really lifetime?

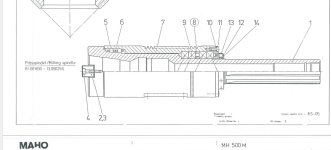

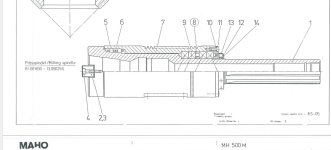

The headstock has some nasty high-dollar bearings, four B719XX series and two custom order ringless clyindrical roller cages, like the deckels had. I want to preserve them as long as possible, but still, I don't want to risk damaging them while disassembly, if not necessary. In the picture, it does not show any kind of seal for the bottom roller cages. The drawing might be simplified, as it is a part drawing, not an engineering plan, but still.

I've posted before, but finally, I arrived at the machinists' league.

I got an 1989 MAHO MH500M model for a very fair price. It is a late manual model with basic Heidenhain DRO, no rapids, Variator feed and speed selection. I think the rapid feed version came around 1990.

It is believed to have few running hours, came from a pneumatic manufacturer's in-house repair facility. The cosmetic flaking is almost untouched on the head and cross slides. Only little wear shows on the edge of the vertical flat ways where the heavy column rides. It has tilting table, so I plan to compensate most of the sagging, if exists.

More pics: Google drive link (sorry, too high res pics)

I believe there are some forum members who had machines like these, so if you see it, your advice is welcomed!

It needs some TLC, but otherwise ready for action. My biggest sorrow is that the original plastic oil fill and drain reservoirs are cracked thus leaking some oil. These pieces are unobtainable, of course.

My first question would be, Is lifetime-lubrication means really lifetime?

The headstock has some nasty high-dollar bearings, four B719XX series and two custom order ringless clyindrical roller cages, like the deckels had. I want to preserve them as long as possible, but still, I don't want to risk damaging them while disassembly, if not necessary. In the picture, it does not show any kind of seal for the bottom roller cages. The drawing might be simplified, as it is a part drawing, not an engineering plan, but still.