Hey guys,

I have a 2001 Mazak Integrex 100-IISY, which has a 10k KMX spindle. My spindle orientation was off, and I adjusted it using variable SP07. However, I discovered that when the milling spindle clamps, even after being orientated, the spindle moves out of orientation by about 0.5 deg. You can actually see the holder turn slightly when the clamp is activated.

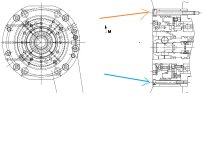

Called Mazak, and they said to pull the front cover off and attempt to adjust the high-index coupling. The process sheet they sent doesn't appear to be for the KM spindle though, and I don't want to tear into this machine any further until I've got a better understanding of what I'm doing. Does anybody have some advice?

I have a 2001 Mazak Integrex 100-IISY, which has a 10k KMX spindle. My spindle orientation was off, and I adjusted it using variable SP07. However, I discovered that when the milling spindle clamps, even after being orientated, the spindle moves out of orientation by about 0.5 deg. You can actually see the holder turn slightly when the clamp is activated.

Called Mazak, and they said to pull the front cover off and attempt to adjust the high-index coupling. The process sheet they sent doesn't appear to be for the KM spindle though, and I don't want to tear into this machine any further until I've got a better understanding of what I'm doing. Does anybody have some advice?