handsonman

Plastic

- Joined

- Apr 30, 2019

I recently had a situation where my 3PH power supply had an arc happen at the bus bar/circuit breaker connection when I turned on the main power switch on my QT-15 /CAM-2. I cleaned the breaker connections and moved the breaker to a new spot on the bus bar. I checked the line voltage, and it seems to be adequate.

But now the machine won't power up completely. Turning the main switch ON will power up the cabinet cooling fans and the spindle and servo drives; which are displaying codes. Spindle drive shows an E7 which is an alarm of some sort.

So, SOME power is getting through as it should.

Now when I press the control start button, I hear a contactor click but the hydraulics don't power up and the monitor won't come on completely.

If I hold the start button in, the monitor will light up with only a black and white static image but will not stay on if I take my finger off the button.

I have an electrical manual for the machine, but it doesn't really explain the sequence of events upon start up.

I have checked the 3 automotive fuses below the spindle drive and they are OK and also checked for any other tripped breakers or blown fuses and found nothing obviously tripped or blown.

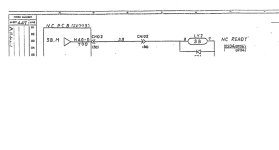

It seems to me, there's a contactor that needs energized to allow power to flow through other parts of the system upon start up.

Like I said, I can hear a contactor "click" but nothing powers up. So the power is being held up somewhere by something.

If anyone has had similar experiences and could advise some items to check or how to remedy this situation, I would greatly appreciate it. I have a call into a local service tech, but have no idea when they will have time to check my machine out. And of course, work is backing up.

TIA

But now the machine won't power up completely. Turning the main switch ON will power up the cabinet cooling fans and the spindle and servo drives; which are displaying codes. Spindle drive shows an E7 which is an alarm of some sort.

So, SOME power is getting through as it should.

Now when I press the control start button, I hear a contactor click but the hydraulics don't power up and the monitor won't come on completely.

If I hold the start button in, the monitor will light up with only a black and white static image but will not stay on if I take my finger off the button.

I have an electrical manual for the machine, but it doesn't really explain the sequence of events upon start up.

I have checked the 3 automotive fuses below the spindle drive and they are OK and also checked for any other tripped breakers or blown fuses and found nothing obviously tripped or blown.

It seems to me, there's a contactor that needs energized to allow power to flow through other parts of the system upon start up.

Like I said, I can hear a contactor "click" but nothing powers up. So the power is being held up somewhere by something.

If anyone has had similar experiences and could advise some items to check or how to remedy this situation, I would greatly appreciate it. I have a call into a local service tech, but have no idea when they will have time to check my machine out. And of course, work is backing up.

TIA