non

Have been fighting this alarm off and on for a long time. Lately it has a tendency to chuck a tool if not oriented first. Service reps think spindle needs replacing. though they are not completely wrong, It doesn't make the noise until it orients. new spindles are not cheap and it still has a year or maybe more left in it. I only happens on tool changes in case I didn't make that clear. machine is a 2005

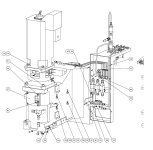

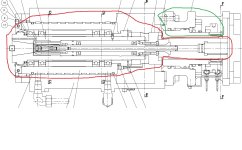

Spindle itself or AC motor? Attached picture ...is this how your spindle looks like? Sounds like PLG sensor needs to be checked to see if you have proper A,B and Z voltages, before someone wants to start replacing parts.

Technically, PLC sends ORIENT command, spindle starts to rotate at slow speed till it sees Z pulse to be able to stop at the orient offset angle (if there is one). At the same time NC must report spindle amplifier zero speed. The way I understand Alarm 244: spindle doesn't stop in a certain period of time or after passing Z phase.

Sounds like electrical problem, either PLG or Spindle amplifier (an amplifier is less likely)

244 ZERO SIGNAL OFF IN SPDL ORIENT

(F44)

The spindle zero speed check signal was set

OFF while the orient check signal was ON.

Machine condition:

Feed hold

Address:

Y3A6, X324 from the Spindle Control