Hi to all,

I recently bought a Mazak Twin turret Quick Slant 30N from a company.

A little history of this Mazak, the machine had run years without huge problems according to the company, daily making hydraulic pistons as its only job. As they bought a bigger Haas, the Mazak need to make some room for the Haas, so I bought this nice lathe for my workshop. Unfortunately, i never saw the machine working, it was just being moved when i went looking it. But I trusted the company that the machine works without problems.

So, I was very happy about this purchase. I brought it home, get it in, give it a clean, all good until I powered up few days ago...

I switched on the main switch, cooling fans are running, so all seems good.

Next step, switch on the NC control. Red led next to the ON button comes on, some relays are kicking in, hydraulic pump delivers pressure, spindle motor fan comes up. So far, so good.

But then nothing happens anymore except for the NC alarm led that comes on. No CRT display, no ready led, no movement of the turret, tailstock, spindle, ...

Looks like the NC control is almost completely dead.

Next day, I resumed to try getting this Mazak alive. But it gets worse. When pushing the ON button, relays kick in but as soon as I stop pushing the ON button, machine goes back to off state. Tried a couple of times, no succes...

15min later, tried again. Machine goes in ON state together with the led in the ON button but that is all, no hydraulic pressure an no cooling fans.

Continuing today, I powered up the Mazak, Relays kick in, hydraulic pump along with fans come on but still no display. Only change is the NC alarm led isn't on.

My first thought was the backup batteries are dead. Machine hasn't been powered for about 14 days until now.

I measured the voltage off the 3 backup batteries: FX784-8: 3.71V, FX784-9: 3.92V, FX727: 3.84V

Anyway, I ordered 3 new 1500mAh NiMH phone batteries to be sure they are new and good. Hopefully I get them this week.

I checked the leds on the boards:

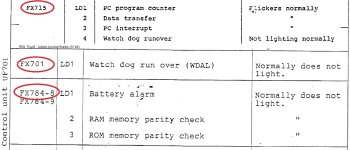

FX 701: WDAL is off but after a certain time it comes on.

FX784-8: PE1 is on, PE2 is off

FX 715: AL off, IT blinks, BA is on but very weak, RDY is on.

Measured the voltage to de CRT which is 106V, should be ok. Fan behind the CRT is running.

Can someone give me advise about this?

Now I am blaming myself that I bought this Mazak without seeing it working...

My last option is to retrofit this machine with a CS-Lab CSMIO control based on Mach3 but i would definitely like to try the mazatrol control, only if the repair cost is within limits.

Last two days, I got a lot of information from this forum about Mazak controls so hopefully, I get this Mazak saved from the scrapyard with a little help.

Thanks in advance!

KR, Bart

I recently bought a Mazak Twin turret Quick Slant 30N from a company.

A little history of this Mazak, the machine had run years without huge problems according to the company, daily making hydraulic pistons as its only job. As they bought a bigger Haas, the Mazak need to make some room for the Haas, so I bought this nice lathe for my workshop. Unfortunately, i never saw the machine working, it was just being moved when i went looking it. But I trusted the company that the machine works without problems.

So, I was very happy about this purchase. I brought it home, get it in, give it a clean, all good until I powered up few days ago...

I switched on the main switch, cooling fans are running, so all seems good.

Next step, switch on the NC control. Red led next to the ON button comes on, some relays are kicking in, hydraulic pump delivers pressure, spindle motor fan comes up. So far, so good.

But then nothing happens anymore except for the NC alarm led that comes on. No CRT display, no ready led, no movement of the turret, tailstock, spindle, ...

Looks like the NC control is almost completely dead.

Next day, I resumed to try getting this Mazak alive. But it gets worse. When pushing the ON button, relays kick in but as soon as I stop pushing the ON button, machine goes back to off state. Tried a couple of times, no succes...

15min later, tried again. Machine goes in ON state together with the led in the ON button but that is all, no hydraulic pressure an no cooling fans.

Continuing today, I powered up the Mazak, Relays kick in, hydraulic pump along with fans come on but still no display. Only change is the NC alarm led isn't on.

My first thought was the backup batteries are dead. Machine hasn't been powered for about 14 days until now.

I measured the voltage off the 3 backup batteries: FX784-8: 3.71V, FX784-9: 3.92V, FX727: 3.84V

Anyway, I ordered 3 new 1500mAh NiMH phone batteries to be sure they are new and good. Hopefully I get them this week.

I checked the leds on the boards:

FX 701: WDAL is off but after a certain time it comes on.

FX784-8: PE1 is on, PE2 is off

FX 715: AL off, IT blinks, BA is on but very weak, RDY is on.

Measured the voltage to de CRT which is 106V, should be ok. Fan behind the CRT is running.

Can someone give me advise about this?

Now I am blaming myself that I bought this Mazak without seeing it working...

My last option is to retrofit this machine with a CS-Lab CSMIO control based on Mach3 but i would definitely like to try the mazatrol control, only if the repair cost is within limits.

Last two days, I got a lot of information from this forum about Mazak controls so hopefully, I get this Mazak saved from the scrapyard with a little help.

Thanks in advance!

KR, Bart

Last edited: