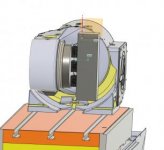

We are looking to add one of the new TRT's to our vf2ss to replace a HRT210. I am worried about rigidity and brake torque.

My main concern is in the op shown we will be running a 1" insert tsc drill through the length of the billet in the shown position. We are currently doing this on a traditional 4th axis rotary with no issues. However I am concerned with the adding of the additional axis and the way the force would now be distributed that we may run into some issues. Is anyone out there running these new TRTs? Do you like them? Are they rigid enough with the A at 90? What do you mill on it?

We would be getting the break booster to assist no matter what but this is a very expensive addition for it not to be able to perform as needed. There are ZERO videos other than one from haas were they take any thing near a "heavy cut" or drill on the new TRT.