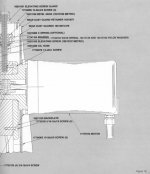

Spindle cartridge attaches to motor with 4 allen bolts. (its a C face motor)

Motor is factory balanced to spindle after assembly so if you want to put it back together right you need to pull the motor straight out mark the "up" on the motor coupling and the spindle coupling so you can match them back up when putting back together.

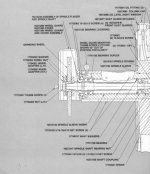

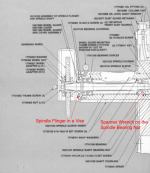

Sounds like you have lost preload. This is controlled by the wave springs part# 17748701 in front of the REAR bearing.

Note that the front angular bearings are mounted in the same direction (tandem DT) so without this pulling force they are free to rattle around.

The rear bearing must float in it's hole for this to work. There is a section in the manual for testing this preload.

One should also be careful when side wheeling with back of the wheel on this machine not to overcome this preload.

View attachment 367664

When the cartridge is removed from the motor take off the rear spider coupling. Then remove the spanner nut part# 16213147 and the spindle shaft will pull out through the front.

This is a very easy spindle to rebuild but this problem has to be addressed and the price of the super precision bearings used will likely give you a heart attack.

Everything must be super clean and high quality (preferably filtered) spindle grease should be used.

Bob