Hi all, I just purchased a 1961 (I think) DoAll D10-30 surface grinder and have to convert it from 440 to 220.

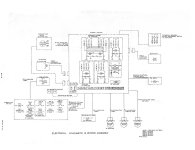

I bought a new rotary 3 phase convertor from American Rotary to run it but I am not an electrician so converting everything to 220 is a bit above my pay grade. I know how to change the motors to low voltage. So I am planning on eliminating the step down transformer in the electrical cabinet and just running 220 into it. I'll rewire the motors to low voltage. The 2 main concerns I have are :

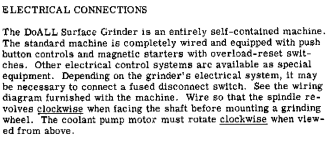

1) Which direction does the hydraulic pump/motor turn? as I may get direction wrong when wiring.

I would hate to spin wrong way and wreck hydro pump.

2) what voltage does my Selectron get? as near as I can tell it is model LV-24. Tag says DC 24 volts 240 AC.

does that mean that input is 220 single phase ? The last thing I want to do is smoke the Selectron controller.

any help would be greatly appreciated...Barry

I bought a new rotary 3 phase convertor from American Rotary to run it but I am not an electrician so converting everything to 220 is a bit above my pay grade. I know how to change the motors to low voltage. So I am planning on eliminating the step down transformer in the electrical cabinet and just running 220 into it. I'll rewire the motors to low voltage. The 2 main concerns I have are :

1) Which direction does the hydraulic pump/motor turn? as I may get direction wrong when wiring.

I would hate to spin wrong way and wreck hydro pump.

2) what voltage does my Selectron get? as near as I can tell it is model LV-24. Tag says DC 24 volts 240 AC.

does that mean that input is 220 single phase ? The last thing I want to do is smoke the Selectron controller.

any help would be greatly appreciated...Barry