RC Mech

Stainless

- Joined

- Jul 21, 2014

- Location

- Ontario, Canada

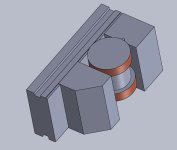

Have a lower die to grind, picture a 4” dia hardened D2 puck 2.5” tall with a 1.5” to 1.25” stepped bore in it. Inside bore, a hardened D2 bushing with a hat sits, hat is 1.499” dia and around 1.5” tall.

The face I need to grind is the side the bushing slips in from. On the bottom, bushing is about 0.020-0.030” from making contact with the mag chuck. Hence the question.

Is the mag flux enough thru the part to hold the assembly together? There are no other means.

Went down the thought process of parallels and stacking gauge blocks. Thought better to ask.

The face I need to grind is the side the bushing slips in from. On the bottom, bushing is about 0.020-0.030” from making contact with the mag chuck. Hence the question.

Is the mag flux enough thru the part to hold the assembly together? There are no other means.

Went down the thought process of parallels and stacking gauge blocks. Thought better to ask.