rhb

Aluminum

- Joined

- Apr 27, 2019

- Location

- A small town in central Arkansas

My apologies if everyone else knows this already. But this might save someone else from reinventing the wheel.

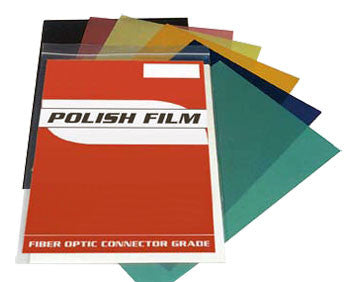

I have for many years used wet or dry SiC paper on a B grade 9 x 12 plate for lapping. I wet both sides of the paper and press it down on the plate with my fingers. I suspect a lot of people do this. Good paper (e.g. 3M) stays flat. Bad paper curls at the edges.

Today I was evaluating some 7000-15000 grit paper I bought via Amazon which was made in China but has "German Technology" printed on the back.

For some reason I got the idea of using the soft rubber printer's brayer I use for spreading spotting media to stick the paper down. The result blew my mind. The adhesion was so strong that the paper simply would not slide. It would lift off with no effort, but was extremely resistant to shear which is what you need for lapping.

Using water only lets you switch grits, or wash off swarf effortlessly. Peel the paper up, rinse it off, wipe off the plate and stick the paper back down. Done properly the plate will experience almost no wear.

I'd been planning to make a set of Robin's sanding plates in several grits, but after discovering what a change the brayer made I'm sticking with water and stone. The brayer will even control horrible paper for a while. Stuff that curls up into a 2" tube when it dries.

Reg

I have for many years used wet or dry SiC paper on a B grade 9 x 12 plate for lapping. I wet both sides of the paper and press it down on the plate with my fingers. I suspect a lot of people do this. Good paper (e.g. 3M) stays flat. Bad paper curls at the edges.

Today I was evaluating some 7000-15000 grit paper I bought via Amazon which was made in China but has "German Technology" printed on the back.

For some reason I got the idea of using the soft rubber printer's brayer I use for spreading spotting media to stick the paper down. The result blew my mind. The adhesion was so strong that the paper simply would not slide. It would lift off with no effort, but was extremely resistant to shear which is what you need for lapping.

Using water only lets you switch grits, or wash off swarf effortlessly. Peel the paper up, rinse it off, wipe off the plate and stick the paper back down. Done properly the plate will experience almost no wear.

I'd been planning to make a set of Robin's sanding plates in several grits, but after discovering what a change the brayer made I'm sticking with water and stone. The brayer will even control horrible paper for a while. Stuff that curls up into a 2" tube when it dries.

Reg