I think your opening ideas and suggestions are pretty good, so hard to comment on them.

I did have some ideas I'm sure you saw, but maybe others have comments on in post #10 here:

New moderator intro

I was thinking about something else. Sometimes its hard to get the ball rolling, or decide how to present, or write it out. I'm a slow writer and might spend hours prepping and thinking on it. I see guys like thermite or EG write a page of material in 5 minutes, and I don't know how they do it.

I consider stickies an ongoing project. I can add or edit them over very long periods of time, so it does not need to be 100% complete at first writing. . . But also, stickies hang around for years, so how do I want it to look ?

One example could be very simple. You have topics in bold, and link various links under each particular topic. This simple and easy approach I took here:

Major Rebuilds, Repairs, & Info Per Manufacture

And as time passes, I come across threads to add to it. I just edit and drop a link in.

Another similar and simple style:

The Sticky Archives of South Bend Lathes

Now if you want something with more style, I'd recommend looking at the work Paula did in South Bend. The links are in bold and blue, and she wrote her own description following each link. Very nicely detailed. I've been working on updating and editing these a bit, and found myself compelled to sort of copy and paste her style as it just looks so nice. As far as moderators go, she just operated on a whole 'nother level, and put so much thought and detail in everything she's done:

South Bend Links: Sources for Info, Parts, and Supplies

Now I don't know coding the way she does. So I click edit to look at the format. I then copy end sections of the code to make it present the same way. Example, look at this thread:

Noteworthy Threads

Now as moderator of this section, click "edit" on my post. Look at the code for the link and description (16" SB Spindle Bearing Question(s)):

16" SB Spindle Bearing Question(s) - This thread, by 'Henro' delves into the intricacies of South Bend spindle bearing re-fitting. While the subject lathe is a 16", many of the principles apply to others sizes as well.

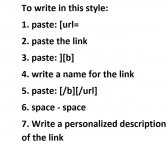

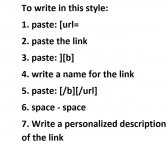

Funny story for all of you, I tried writing the code as an example. . .but the code does what its supposed to,

. So I can't write it where its visible. I'll try screen shoting it: