LowEnergyParticle

Cast Iron

- Joined

- Jul 26, 2004

- Location

- Beaumont, near Houston

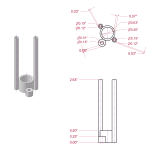

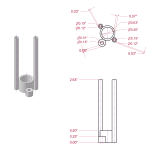

I would like to ask for help on using resistance welding to weld together 4 small 304 S/S tubes. I need to fabricate a jig to hold the tubes together as shown in the drawing and then weld them. We don't own any resistance welding or spot welding equipment, so I'd be starting off from scratch.

We've built similar assemblies in the past by oven brazing them. This worked pretty well, but our setup was pretty primitive and so it took a long time and used a lot more energy than a tightly controlled resistance welder.

I was thinking of a single return electrode going in the central 1/2" ID tube, and then a single hot electrode that wrapped around the the outsides of the 3 smaller tubes and pressed the whole mess against a non-conductive surface. But I don't know much about it. So, would someone please set me on the right path here?

Thanks very much, and a Happy New Year to all!

Dave

We've built similar assemblies in the past by oven brazing them. This worked pretty well, but our setup was pretty primitive and so it took a long time and used a lot more energy than a tightly controlled resistance welder.

I was thinking of a single return electrode going in the central 1/2" ID tube, and then a single hot electrode that wrapped around the the outsides of the 3 smaller tubes and pressed the whole mess against a non-conductive surface. But I don't know much about it. So, would someone please set me on the right path here?

Thanks very much, and a Happy New Year to all!

Dave