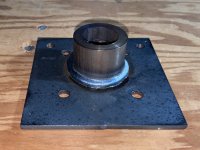

I couldn't find any buyers for my old 9" Troyke rotary table, so I combined it with some drill press parts to make a welding positioner. As pictured the table has a speed range of around .5 rpm to 5 rpm, and the range can be changed via timing pulley changes. I am adding a 12" diameter face plate with 1" standoffs.

I have a grounding plan in mind, but there is another issue. The cheap Chinese variable speed gear motor I used works great, but its capacitor doesn't like it when you switch it on at a pre-determined speed setting. When I use a a foot pedal to turn it on the capacitor freezes up. I suspect that a U.S. made motor.controller without that shortcoming would probably cost twice as much as the rest of the project.

I have a grounding plan in mind, but there is another issue. The cheap Chinese variable speed gear motor I used works great, but its capacitor doesn't like it when you switch it on at a pre-determined speed setting. When I use a a foot pedal to turn it on the capacitor freezes up. I suspect that a U.S. made motor.controller without that shortcoming would probably cost twice as much as the rest of the project.